A poor choice in machine protection not only shortens the equipment’s lifespan; it also compromises safety and slows down production.

Every production system has its own unique characteristics, and not all protection solutions are suitable for all environments. At Lluis Creus, we see this every day: plants that replace bellows every month because they aren’t designed for their environment, or facilities that install spirals where chemical sealing is required.

This article will help you make an informed decision: when should you use bellows, spiral, or curtain as a protection element?

Why is it key to choose well?

The production of bellows and machine protection elements must be carried out considering the type of movement, environmental conditions, and accessibility for maintenance. Inadequate protection leads to failures such as:

- Accumulation of dirt or moisture on critical parts.

- Damage from abrasion or corrosion.

- Risks to operators due to exposure to moving parts.

- Unplanned downtime due to premature wear.

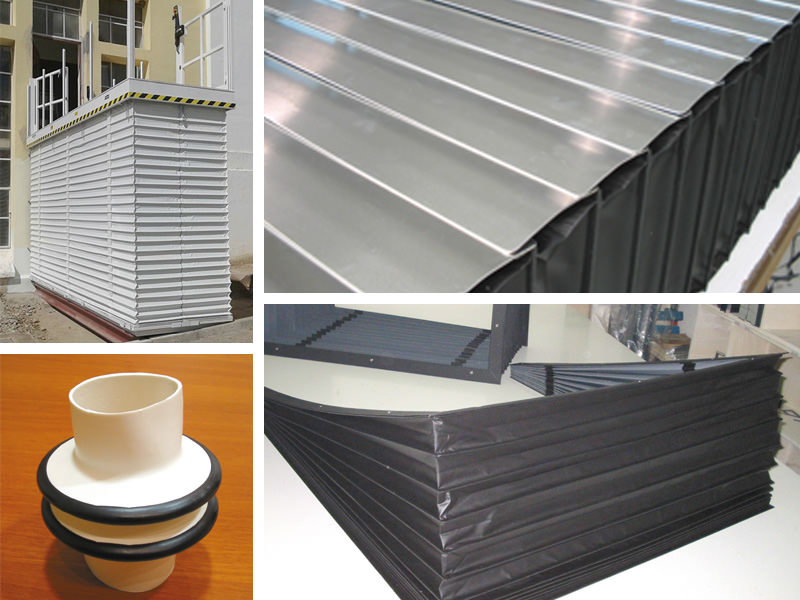

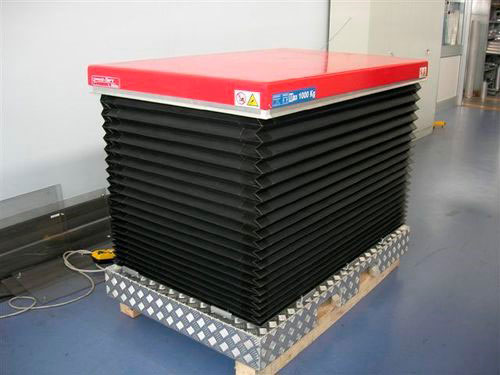

1. INDUSTRIAL BELLOWS

The most versatile and safe solution for complex movements.

Advantages:

- Adaptable to any travel (linear, axial, telescopic).

- Manufactured in materials resistant to heat, chemicals, or moisture.

- Completely isolate moving areas, preventing external contamination.

Ideal applications:

- CNC machines, lathes, pneumatic and hydraulic actuators.

- WWTPs with harsh environments.

- Machines with safety regulatory requirements.

When to avoid them?

If constant access is required or there is no space to fold the bellows.

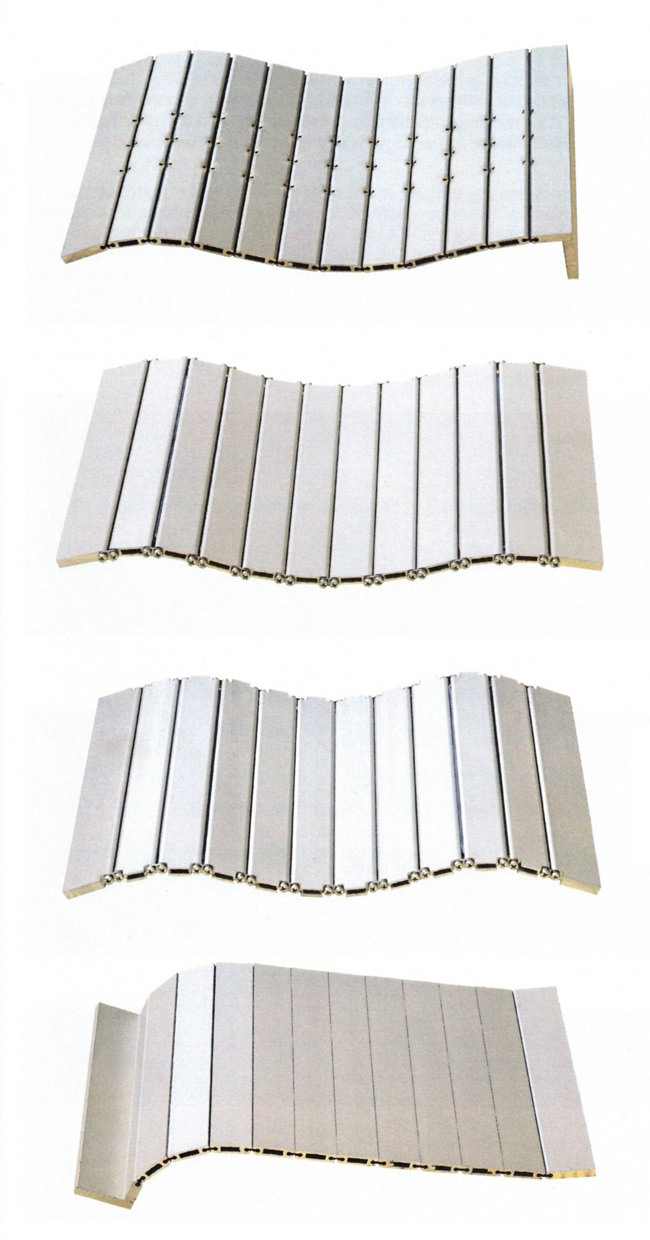

2. PROTECTIVE SPIRALS

An economical and effective option for exposed shafts or screws.

Advantages:

- Good resistance to dust and small particles.

- Easy to install and maintain.

- Low cost and rapid manufacturing.

Ideal applications:

- Feed axes, machines in dry or mild environments.

- Mechanical production or packaging with repetitive movements.

When to avoid them?

In humid environments, with exposure to chemicals, or where a hermetic seal is required.

3. TECHNICAL CURTAINS

Flexible protection for passageways or process separations.

Advantages:

- They allow opening and closing of areas without disassembling components.

- They are made of fabrics adapted to thermal, chemical, or mechanical risks.

- Suitable for delimiting work areas or isolating hazardous areas.

Ideal applications:

- Welding booths, industrial cleaning, chemical handling areas.

- Environments requiring frequent access and partial visibility.

When to avoid them?

If there are moving parts without direct visibility or if there is a risk of entrapment.

How do you know what you need?

At Lluis Creus, we apply three technical criteria before designing any protection:

- Type of movement: What does the machine do and how often?

- Industrial environment: Is there heat, chemicals, humidity, or electrical risk

- Accessibility: Is it a transit area or a periodic inspection area?

With this information, we choose between bellows, spiral, or curtain, or even design a hybrid solution.

Conclusion

It’s not just about covering part of the machine. It’s about protecting people, processes, and equipment with technical intelligence.