When the catalog doesn’t fit, it’s time to design from scratch.

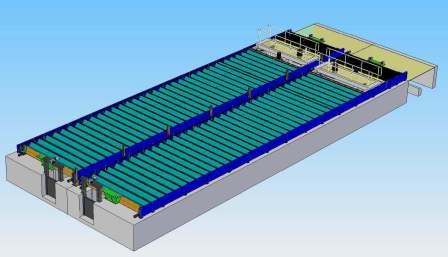

In demanding industrial environments, choosing the right machine protection can’t simply be a matter of finding a part that “fits.” Bellows, which protect moving components from contaminants, heat, or impacts, only fulfill their purpose if they are manufactured according to actual operating conditions. But what does custom bellows production really mean? And why is it so crucial in sectors such as water treatment (WWTP), food, and industrial automation?

Why isn’t a standard bellows enough?

The most common misconception is that a bellows simply having the correct dimensions is enough. However, there are factors that are equally or more important:

- Type of movement (linear, telescopic, rotary)

- Frequency of use (hours per work day)

- Temperature (ambient or generated by the machine itself)

- External influences (dust, oil, steam, chemicals)

- Accessibility for maintenance

Standard bellows are designed for a very general range of conditions. This means they wear out faster or, worse, do not provide adequate protection and fail when they are most needed.

What does custom bellows production entail?

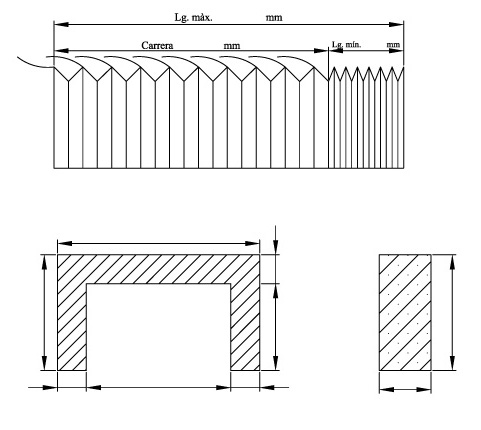

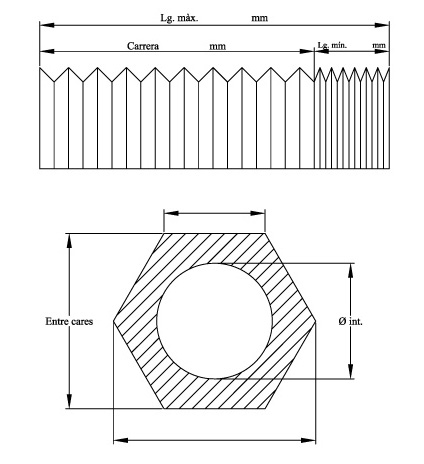

At Lluis Creus, we start from a clear principle: design protection based on the environment, not a catalog. To achieve this, each bellows is produced following a technical process that includes:

- Analysis of the installation environment

○ We collect thermal, chemical, and mechanical data from the area.

○ We assess the level of exposure and the type of particles present. - Movement analysis

○ We calculate the travel, speed, and cycles per minute.

○ We determine the critical bending points and the available space. - Material selection

○ We use technical fabrics, PVC, silicone, polyurethane, or steel depending on needs.

○ In WWTP plants, for example, materials resistant to chemicals and constant humidity are prioritized. - Technical design

○ We model the bellows in CAD to ensure compatibility and performance.

○ The fastening system is adapted (cable ties, magnets, Velcro, zippers). - Manufacturing under industrial standards

○ The bellows are not only produced with the correct measurements, but also with seams, heat seals, and folds that extend their useful life.

Benefits for the industrial customer

- Greater machine availability: fewer failures and downtimes.

- Improved workplace safety: no exposed parts, no risk of entrapment.

- Long-term cost reduction: a suitable bellows lasts longer and does not require constant replacements.

- Adaptation to the preventive maintenance protocol.

Who needs this type of solution?

- Maintenance managers who want to reduce downtime.

- Industrial safety managers who prioritize safe environments.

- Purchasing managers looking for technical suppliers, not just parts.

- WWTP plants that need solutions resistant to extreme environments.

Conclusion

The production of custom bellows and machine protection elements is not an aesthetic option or a luxury. It is a technical decision that makes the difference between a safe environment and a constant source of breakdowns.

At Lluis Creus, we have been protecting machines, people, and processes for decades. We design solutions from the environment, not from a catalo