In any industrial equipment, dirt doesn’t appear by chance. When a machine starts showing accumulations of dust, shavings, or moisture in areas that should be protected, the usual reaction is to think it’s “normal for the process.” However, in most cases, it’s an early warning that the bellows is no longer sealing properly, and therefore, the machine’s protection is leaving a vulnerable point exposed.

Detecting this problem in time prevents downtime, intermittent failures, and unnecessary wear and tear on components. There’s no need to disassemble the machine or resort to complex diagnostics. Simply observing small details clearly reveals that the bellows has lost its protective capacity.

Recurring dirt is never random.

The first sign appears when a specific area of the machine gets dirty again and again after cleaning. This could be a linear guide, a cover, a housing, or even wiring. If the residue always returns to the same spot, it means particles are entering through the bellows or its immediate surroundings.

This happens because the bellows no longer seals properly: either there’s a gap, the fabric is damaged, or the overlaps don’t align with the actual travel. Industrial machinery guards are designed to block this type of contamination. When this barrier fails, the machine will alert you.

The folds also tell a story: wear, shine, and deformation.

A bellows functions properly when its folds open and close evenly. If any fold begins to show a different shine or wears unevenly, it means it’s rubbing against something during movement. This rubbing, even if minimal, often creates a micro-opening that allows dirt to enter.

A bellows should not have areas that polish themselves. When this happens, it’s not a cosmetic defect: it indicates a mismatch between the bellows’ geometry and the shaft’s dynamics. And in terms of industrial machine protection, this mismatch is an open door to contamination.

When the inside of the bellows shows residue, the problem is advanced.

Seeing dirt inside the bellows is one of the clearest signs that the protection is compromised. The inside should remain clean throughout its lifespan; if shavings, dust, coolant residue, or moisture appear, it means the seal has broken.

This usually happens for two main reasons:

- The material is no longer suitable for the type of residue generated.

- The machine has been upgraded (higher speed, a different tool, a new accessory) and the bellows no longer moves properly with the machine.

In both cases, the consequence is the same: the machine is exposed, and the lifespan of its components is reduced.

Lips and seals that lose their shape: small changes, big effects.

Bellows and other guards for industrial machinery often include lips or seals that ensure closure at certain points. Over time, these elements can deform due to repeated stress, especially if the guard operates outside its intended range.

A poorly positioned seal is not a minor issue: it creates a gap through which fine dust, shavings, or moisture can enter. This small opening is enough to contaminate a guide or sensor and cause intermittent failures that are mistakenly attributed to electrical problems.

Internal moisture is a clear sign of material incompatibility.

When condensation or trapped moisture appears inside the bellows, it’s not solely due to the working environment. In many cases, it’s a symptom that the bellows material isn’t designed for that type of coolant or temperature. Trapped moisture degrades the fabric from within, causing deterioration that progresses without being visible from the outside.

This is especially common in environments where harsh chemicals, oils, emulsions, or coolants are used. If the bellows lacks adequate resistance, it loses its properties and ceases to offer effective protection.

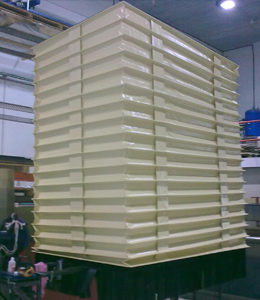

The solution lies in adapting the protection to the realities of the process.

When a bellows stops sealing properly, the problem is usually not solved by simply replacing the part with an identical one. If the environment, movement, or working conditions have changed, the protection must be adapted to this new reality.

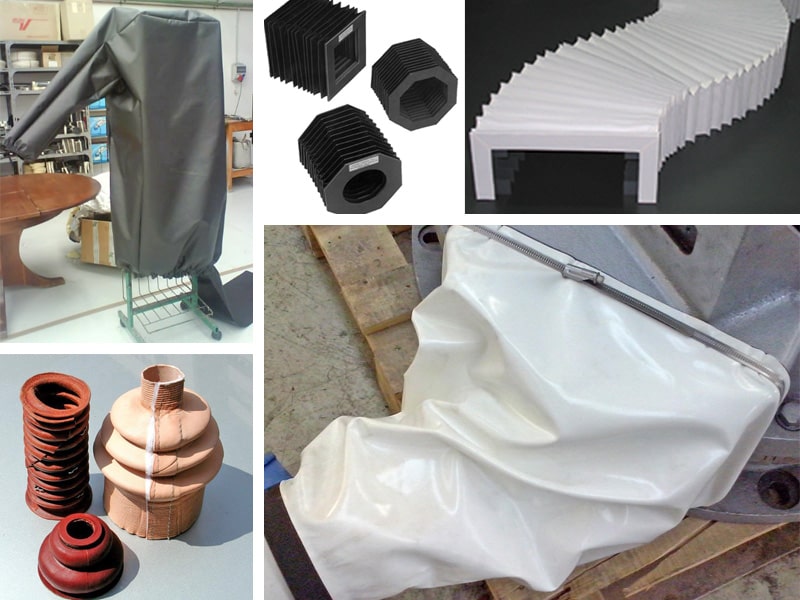

Real-world solutions for restoring effective protection include:

- Choosing a material specifically designed for the type of residue or coolant present in the machine.

- Redesigning closures and overlaps to guarantee a watertight seal, even with complex movements.

- Reinforcing critical areas where stress or impacts are concentrated.

- Adjusting the bellows’ geometry to the current travel, not the original.

These adaptations transform the bellows into a reliable and durable component, capable of continuously and safely protecting the machine.