Ordering a custom bellows is a critical technical decision. A poor specification can lead to premature failures, loss of airtightness, and unplanned machine downtime. Most problems originate not in manufacturing, but in the specification phase.

Common mistakes when ordering custom bellows

Poorly defined design

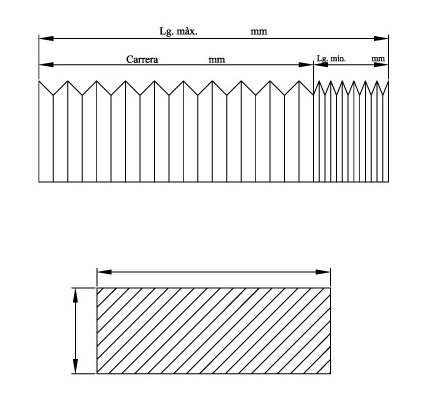

Failing to specify dimensions, travel distances, folds, or fastening systems leads to misinterpretations. This often results in unnecessary stress and a reduced lifespan for the bellows.

Failing to consider actual use

Designing the bellows without considering temperature, contaminants, friction, or actual operating cycles is one of the most common mistakes. A design that looks good on paper may fail in practice.

The importance of clear specifications

A correct order should include:

- Dimensions at rest and in operation.

- Actual stroke and type of movement.

- Environmental conditions.

- Sealing requirements.

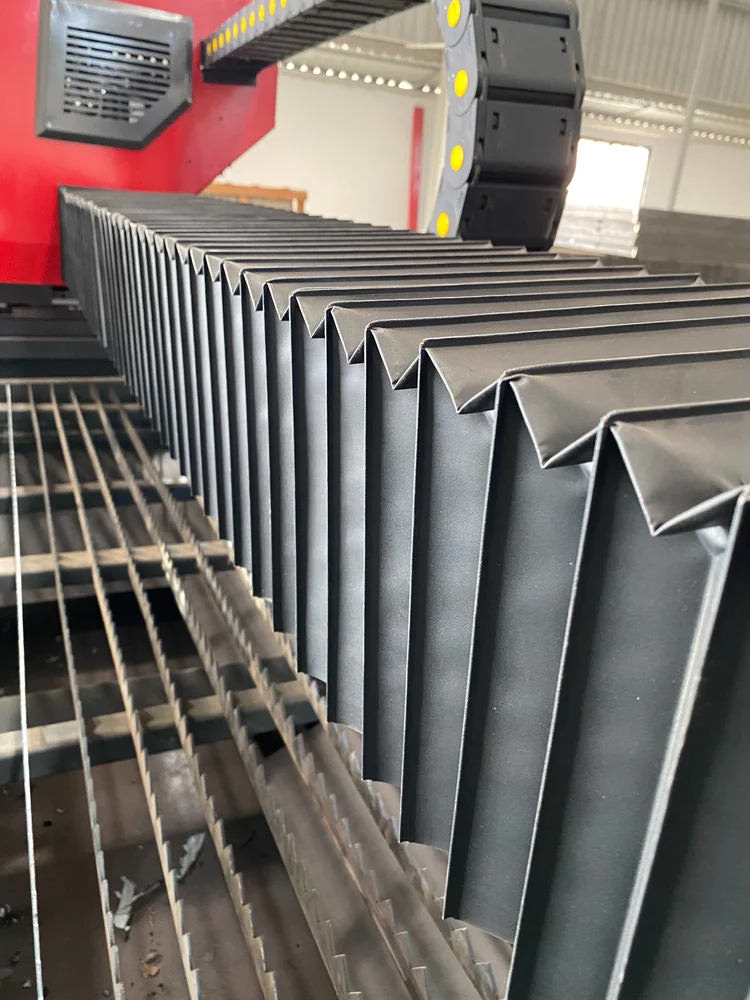

Including diagrams or photographs of the actual application reduces errors and subsequent adjustments.

Material selection

The material should be chosen according to:

- Operating temperature.

- Presence of oils, coolants, or particles.

- Flexibility and strength requirements.

Improperly applied standard materials are often the cause of premature failure.

Dimensions and tolerances

Small dimensional deviations can cause interference, overstress, or breakage. Defining dimensions and tolerances correctly is key to ensuring reliable operation.

Consequences of an incorrect order

- Additional costs for remanufacturing.

- Maintenance delays.

- Unplanned production stoppages.

The impact is usually much greater than the cost of the bellows itself.

Final recommendations

Before confirming an order:

- Review all technical information.

- Validate the design with a specialist.

- Whenever possible, perform a preliminary validation or prototype.

Conclusion

A custom-made bellows works correctly when it is well-defined from the start.

The key is not to replace it faster, but to better design the machine’s protection.