For decades, industrial bellows were made from leather or conventional textiles. However, modern industry demands much more.

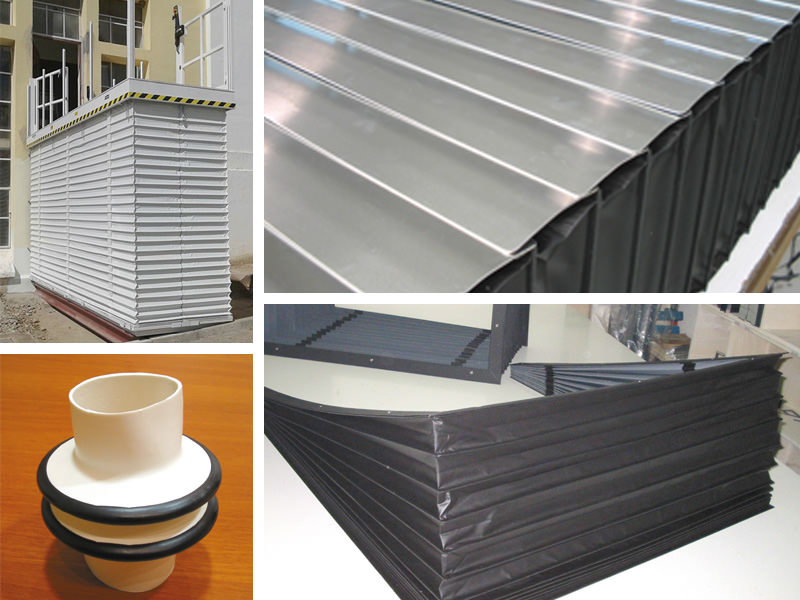

The production of bellows and machine guards has evolved toward the use of advanced materials, capable of withstanding harsher environments and extending the life of the guards.

Why are traditional materials no longer sufficient?

-

Leather degrades in the face of oils and chemicals.

-

Basic textiles cannot withstand extreme temperatures.

-

The flexibility and durability required by automation exceeds the capabilities of conventional materials.

Current technical materials

-

PVC or PU-coated fabrics: resistant to oils and moisture.

-

Kevlar and Nomex: ideal for high-temperature environments.

-

Reinforced plastic composites: a balance between lightness and mechanical strength.

-

Stainless steel or aluminum in metal bellows: maximum durability in abrasive environments.

Advantages of using advanced materials

- Greater wear resistance.

- Dimensional stability in repetitive cycles.

- Medium- and long-term maintenance cost savings.

- Compliance with safety and quality regulations.

Ultimately, choosing the right material means investing in the safety and continuity of production.

At Lluis Creus, we analyze each industrial environment to recommend the ideal material for each bellows.