One of the most common mistakes when replacing a bellows isn’t in the material or the design, but in the measurement. An incorrectly measured bellows creates stress, deforms, interferes with machine movement, or fails prematurely. And when that happens, the problem isn’t the bellows itself, but how it was initially specified.

Measuring correctly isn’t just an administrative procedure. It’s a key technical step to ensure the machine’s protection functions properly and lasts.

Why incorrect measurements cause bellows failures

A bellows operates in constant motion. If the measurements are incorrect:

- It stretches or compresses more than expected.

- Forced folds appear.

- Material wear is accelerated.

- The seal is compromised.

In many cases, problems attributed to bellows quality actually originate from incomplete or incorrect measurements

The first key piece of information: the machine’s actual travel distance.

Before measuring the bellows, it is essential to know the total travel distance of the shaft, guide, or component to be protected. This is not a theoretical measurement, but rather the actual movement under working conditions.

It is crucial to identify:

- Fully extended position.

- Fully retracted position.

- Intermediate positions if there are changes in speed or load.

This information defines the minimum and maximum length of the bellows and determines the entire design.

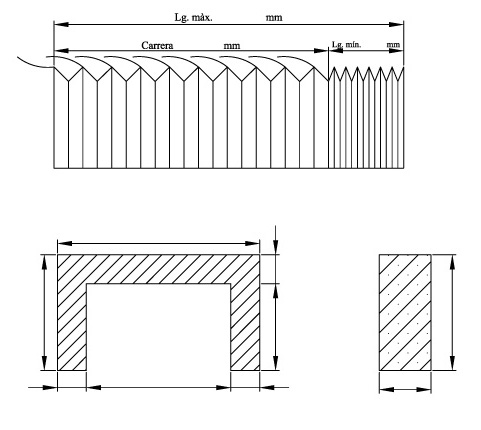

Closed and open length of the bellows

With the bellows’ path clear, the next step is to determine:

- Length of the bellows fully closed.

- Length of the bellows fully extended.

These two measurements allow us to calculate the number of pleats and their geometry. An error here often results in the bellows always working under strain, even if it appears to fit the machine.

Bellows section: actual width and height

The bellows section must be adapted to the available space and the item to be protected. To do this, it is necessary to measure:

- Usable interior width.

- Usable interior height.

- Clearance around the movement.

It is not advisable to adjust the section to the millimeter. The bellows needs clearance to fold correctly without friction or interference.

Mounting type and anchor points

Another common mistake is not correctly defining how the bellows is attached to the machine. It is necessary to identify:

- Type of frame or flange.

- Existing mounting system.

- Available space for anchoring.

The mounting method directly affects the bellows’ durability and its ability to maintain stable machine protection.

Actual working conditions affecting measurement

Measuring without considering the environment is a common mistake. Before ordering a new bellows, consider the following:

- Presence of shavings, dust, liquids, or vapors.

- Operating temperature.

- Cycle speed and frequency.

- Potential impacts or projectiles.

These factors do not change the basic measurements, but they do influence the design of the fold and the bellows material.

Properly documenting measurements prevents errors and delays.

Whenever possible, accompany measurements with:

- Photographs of the machine.

- Simple sketches.

- Clear indication of the direction of movement.

Good documentation reduces subsequent adjustments and ensures the bellows performs its function correctly from the first assembly.

Accurate measurements means better machine protection

A properly sized bellows:

- Operates without tension.

- Lasts longer.

- Effectively protects critical components.

- Reduces downtime and corrective maintenance.

Accurate measurement is the first step toward reliable machine protection.

Are you unsure about measuring your bellows?

If you’re not sure how to measure or if your machine has complex geometries, it’s best to check it before manufacturing the bellows.

An error at this stage often leads to problems later on.

Contact us; we’ll review your application and help you determine the correct measurements so the bellows truly fits your machine.