When a bellows deteriorates repeatedly in the same spot, the pattern is not random. In the field of industrial machine guards, this repetition is a clear sign of a constant cause acting on the same area. Although at first glance it may seem like a material defect or normal wear and tear, this type of repetitive breakage has a much more precise and technical origin.

This article proposes a clear and simple path to analyze why a bellows always fails in the same way, how to interpret the symptoms, and what adjustments will restore stable and long-lasting industrial machine guarding.

1. Understanding the pattern: recurring breakage isn’t wear and tear, it’s a message

The first key to solving this problem is recognizing that a bellows doesn’t break for no reason. Every fold, every area of the fabric, and every seam works according to the geometry of the machine’s movement. If a specific point is always the one that fails, it means that point is facing an unforeseen stress or impact not included in its design.

This type of recurring breakage appears in machines in any sector: machining, automation, packaging, handling, surface treatment, or humid environments. And it always stems from the same technical principle: there is an external factor acting repeatedly on the same area of the bellows.

2. The most common causes: four Sscenarios affecting any type of guard

Although each machine has its own particularities, four possible causes for this type of failure are always repeated in the analysis of guards for industrial machinery.

They are presented here without dramatization or fabricated examples: they are universal causes observable in any plant.

A. Internal stresses caused by incorrect geometry

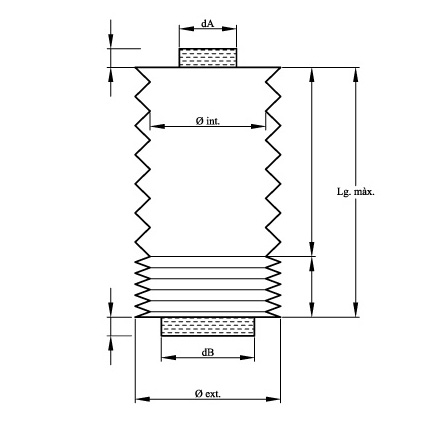

A bellows is designed to fold, extend, and move with it without experiencing stress.

But if:

- the actual travel changes,

- the effective stroke increases,

- or the alignment does not match the design,

a fold can operate outside its natural curve.

This stress accumulates with each cycle and eventually leads to a break in the same location.

B. Continuous friction with a nearby edge or surface

Sometimes it’s not the dynamics of the movement, but the immediate physical environment:

- a sharp corner,

- a sheet metal,

- a casing,

- a metal support or guard.

A gentle but repeated rub is enough for that point of the bellows to wear out faster than the rest. A shine, a more polished feel, or uneven wear will give it away.

C. Constant impact of particles, shavings, or coolant

When an industrial machine guard is exposed to continuous projection of:

- hot shavings,

- abrasives,

- metal dust,

- coolant,

- or moisture,

the areas that receive this impact degrade faster.

This is especially common in partially open machines or in processes where the direction of the debris is always the same.

D. Localized vibrations in a specific area

A large impact isn’t necessary.

Constant micro-vibrations in a support, housing, or structure can be transmitted to the bellows, causing fatigue at the same point.

This type of wear is progressive and can go unnoticed for weeks.

3. How to diagnose what’s happening: signs that don’t require machine disassembly

To identify the source, it’s not necessary to stop production or perform a complex intervention.

A simple visual and behavioral analysis during the cycle can reveal the cause.

Some clear clues:

- Straight-line break → excessive tension or compression.

- Polished or shiny material → continuous friction.

- Frayed or burnt fabric → chip impact or heat.

- Repetitive creases or fatigued material → localized vibration.

- Fold deformation → insufficient geometry for the actual movement.

The pattern is more important than the final break.

Conclusion: Repeated breakage is the warning that allows for improved protection.

When a bellows always breaks in the same place, it’s not the bellows itself that’s failing: it’s the adaptation between the protection and the actual working environment that’s failing.

If the design is adapted to that environment, the lifespan improves dramatically.And most importantly: the protection regains its function within an industrial machinery protection system that not only covers, but truly protects.