Industry 4.0 has not only changed the way production is done; it has also transformed the requirements for machine guarding.

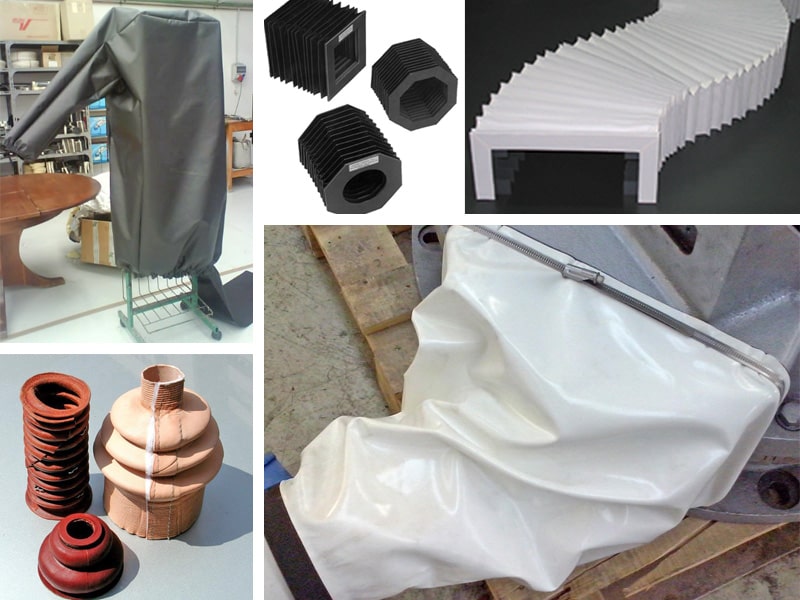

In an increasingly automated environment, the production of bellows and machine guards must adapt to new rhythms, movements, and technical demands.

What changes with automation?

-

-

Speed: Equipment works with faster and more consistent cycle times.

-

Precision: Minimal tolerances require guards that do not interfere with movement.

-

Complex movements: Robotic arms and automated tables require specific 3D designs.

-

Features of a bellows for automated environments

-

Folds designed for thousands of cycles without fatigue.

-

Lightweight materials that reduce resistance to movement.

-

Geometry adapted to multidirectional movements.

-

Easy replacement to minimize downtime.

Direct benefits

-

Reduction in breakdowns due to external contamination.

-

Greater safety for operators and collaborative robots.

- Time saved on preventive maintenance.

Bellows have gone from being an accessory component to becoming an essential ally in industrial automation.

At Lluis Creus, we develop protections that evolve with the pace of the factory of the future.