The challenge of protecting spindles in harsh environments

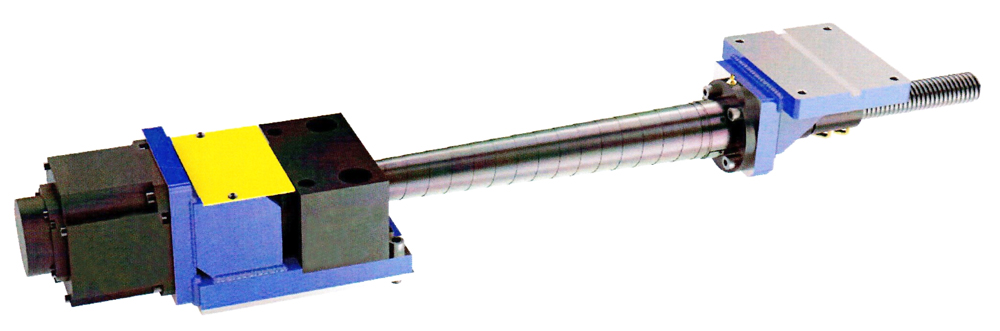

Imagine a machining plant where oil constantly splashes and metal shavings fly uncontrollably. In such an environment, machine spindles and guide columns are highly vulnerable. Maintenance managers know that poor protection can result in unplanned downtime, lost production, and high repair costs. The solution? Metal spirals, a protection system specifically designed to withstand extreme conditions and extend the life of machinery.

What are metal spirals and why are they ideal for oily environments?

Metal spirals are protective elements that enclose screws, guide columns, and shafts, preventing direct contact with dirt, chips, and mechanical stress. Unlike other methods, they are designed to operate in conditions where oil and the absence of fine dust are constant. Their design allows for smooth movement, effortless compression and extension, resulting in greater durability and reduced maintenance.

Key advantages:

- Mechanical resistance: Made of high-quality steel, they withstand impacts and vibrations.

- Adaptability: They can be installed horizontally or vertically with minimal deflection.

- Easy installation: They are supplied in a packaging system that facilitates assembly.

Selection criteria: how to choose the right metal spiral

To select the right spiral, it is essential to consider several factors:

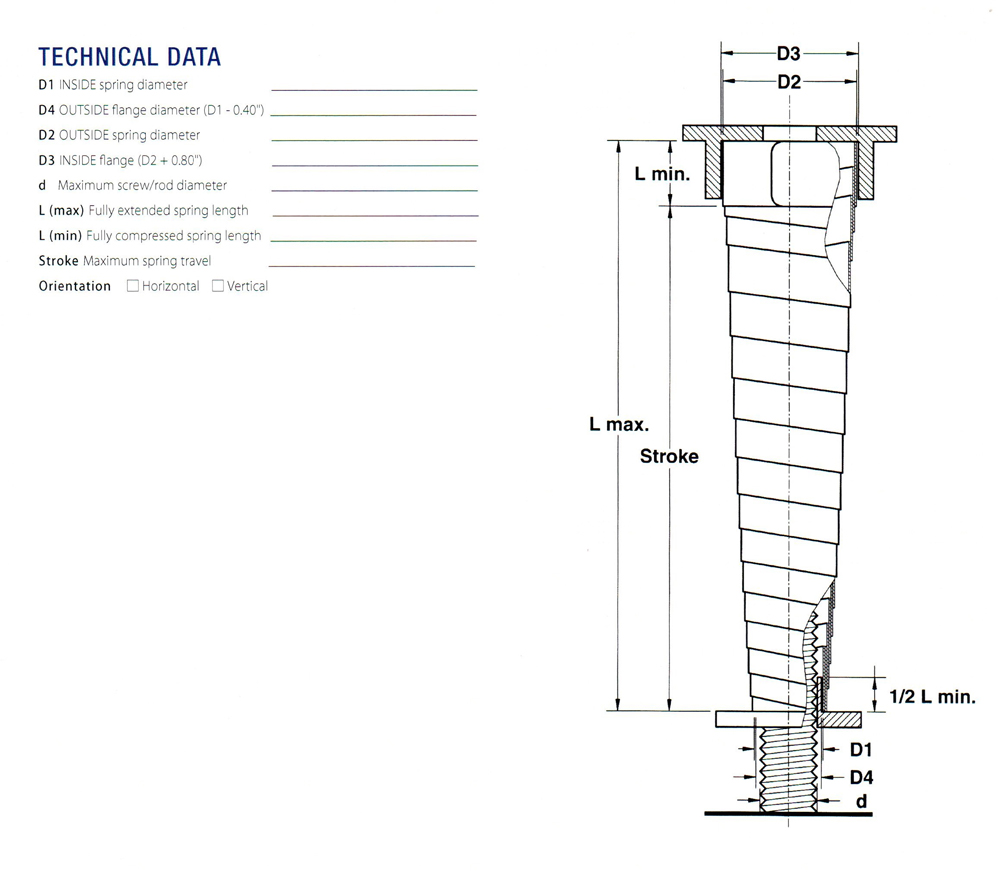

1. Screw diameter and length: Accurately measure the diameter of the element to be protected and the stroke of the machine. A properly sized spiral ensures protection without interfering with operation.

2. Environment: Metal spirals are designed for oily environments without fine dust. If your plant generates a large amount of fine shavings, consider complementing them with a bellows or shutter system to prevent buildup.

3. Mounting orientation: In a horizontal position, the spiral maintains minimal level; in a vertical position, lateral deviation is barely perceptible. Consider the screw weight and travel speed to select the appropriate model.

4. Ease of maintenance: Choose suppliers that offer modular designs and a simple replacement system, reducing downtime.

Best practices to maximize service life

-

Periodic Cleaning: Although spirals are designed for oily environments, regular cleaning will prevent accumulated chips from creating friction.

-

Tension Check: With use, the spiral can stretch. Perform periodic checks to ensure it maintains the proper tension.

-

Personnel Training: Train operators on handling and early fault detection. A trained eye can identify unusual noises or abnormal movements.

Conclusion: safety and efficiency in a single component

Investing in quality metal spirals not only protects your screws and guide columns; it also improves production efficiency, reduces the risk of accidents, and extends the lifespan of your machinery. For maintenance engineers and plant managers, knowing the selection criteria and best practices is key to avoiding costly mistakes.

Do you need personalized advice on metal spirals or other protection solutions? The LluisCreus team has over 150 years of experience in custom solutions and can help you find the ideal option for your application. Contact us and discover how to optimize the protection of your machinery.