Innovation and safety: The future of industrial protection

In modern industry, the safety of machinery and its components is an unavoidable priority. Exposure to agents such as chips, coolants, dust, and extreme temperatures can reduce equipment lifespan, increase the risk of mechanical failure, and lead to unscheduled shutdowns.

With over 50 years of experience, Lluis Creus offers specialized industrial protection solutions designed to extend machinery lifespan, minimize downtime, and ensure compliance with safety regulations. Our Smart Protection line incorporates advanced materials and technologies to provide protection against external agents in demanding industrial environments.

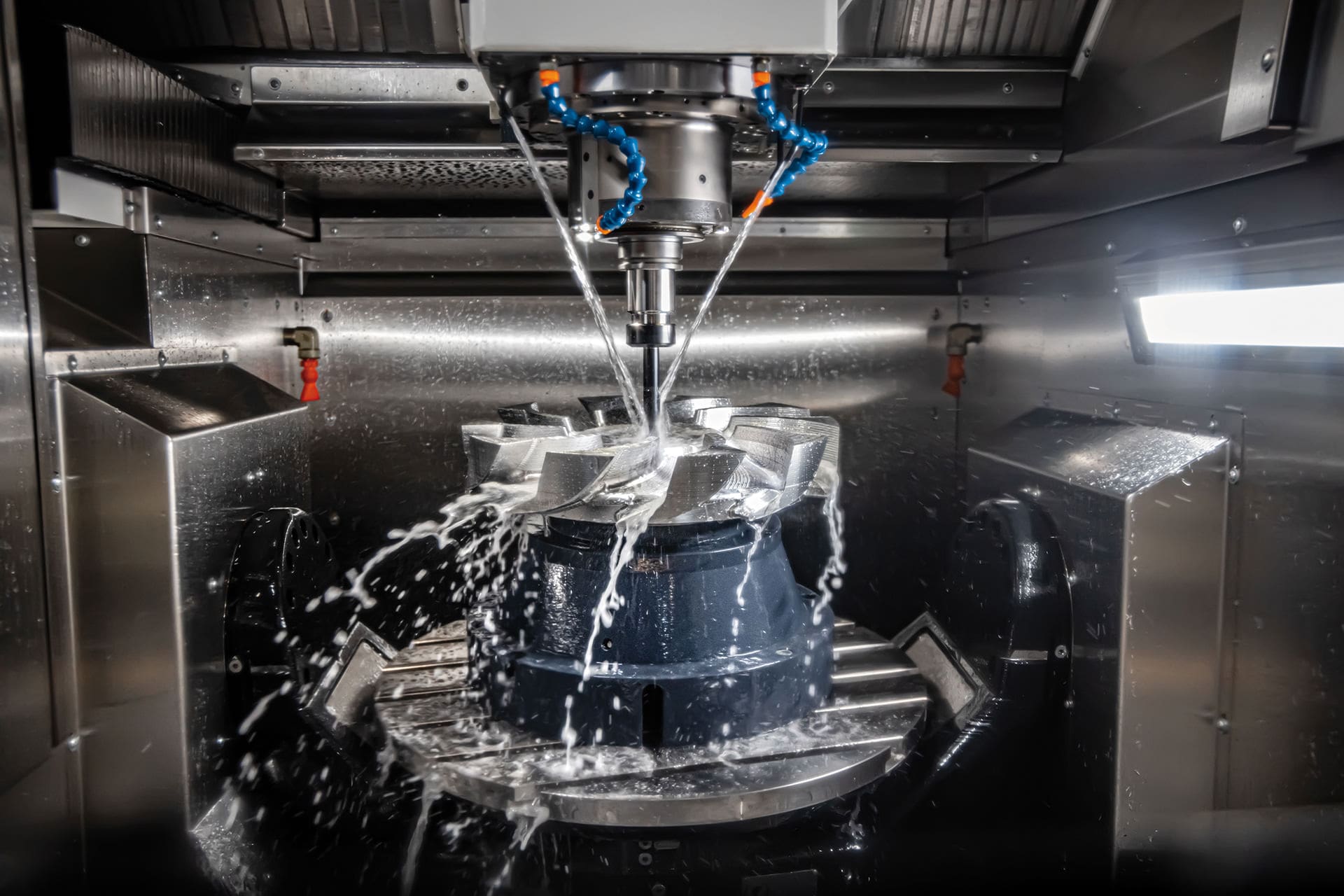

Protection for CNC machinery and precision tools

How to avoid chip damage in CNC machinery

Metal chips generated during machining processes can cause jams, premature wear, and costly breakdowns. To prevent these problems, at Lluis Creus we offer:

a) Square and telescopic bellows that block the entry of debris.

b) Aluminum shutters that protect critical contact areas.

c) Sleeves and compensators designed to enclose the most exposed components.

These solutions reduce chip buildup, preventing damage to guides, spindles, and transmission systems.

Coolant protection for machine tools

Coolant is essential for machining, but it can also cause corrosion and leaks in internal components. To protect machine tools, the following are recommended:

- Metal coils resistant to industrial liquids.

- Flexible covers with hermetic seals to prevent leaks.

- Customizable protection systems based on equipment exposure.

These products ensure that the coolant performs its function without compromising the integrity of the equipment.

Protecting screws, linear guides, and hydraulic cylinders

How to prevent premature wear in industrial screws

Industrial screws are subject to constant wear due to friction and environmental contamination. To extend their lifespan, at Lluis Creus we recommend:

a) Protective bellows specifically designed for screws.

b) Impact- and dirt-resistant metal spirals.

c) Controlled lubrication and protection against dust and chips.

These measures reduce the need for maintenance and extend the equipment’s operating time.

How to protect linear guides from wear

Linear guides are critical components in CNC machines and automated systems. Lack of protection can lead to premature wear and compromise machining accuracy. To prevent this, we offer:

- Heavy-duty bellows that cover the guides without affecting movement.

- Aluminum shutters for maximum protection without compromising access.

- Hermetic cover systems against dust and contaminants.

These solutions ensure the stability and accuracy of the guides over time.

Solutions to protect hydraulic cylinders

Hydraulic cylinders must operate under demanding conditions without being damaged by contaminants or extreme temperatures. The best protection options include:

a) Flexible sleeves that adapt to the cylinder’s movements.

b) Covers resistant to oils and hydraulic fluids.

c) Customized protection systems for each application.

These elements prevent seal degradation and pressure loss in the cylinders.

Protection against environmental factors in industrial machinery

Solutions for dust contamination in machinery

Dust is one of the greatest enemies of industrial machinery, as it accumulates on critical components and affects their performance. At Lluis Creus, we offer:

✔ High-tightness bellows to block dust entry.

✔ Protective covers that prevent debris buildup.

✔ Metal coils with a non-stick design to minimize particle accumulation.

These systems ensure cleaner and more efficient operation.

Corrosion prevention in industrial equipment

Exposure to moisture and corrosive chemicals can drastically reduce the lifespan of equipment. To prevent this, we recommend:

- Anti-corrosion coatings on coils and bellows.

- Flexible covers resistant to aggressive chemicals.

- Hermetic seals to prevent leaks.

These solutions protect equipment in highly corrosive environments.

Conclusion

Industrial protection has evolved with innovative materials and specific solutions that improve the safety and efficiency of machinery. At Lluis Creus, our Smart Protection line offers products designed to withstand extreme conditions, extend equipment life, and reduce downtime.

Discover our customized solutions and take your machinery protection to the next level.