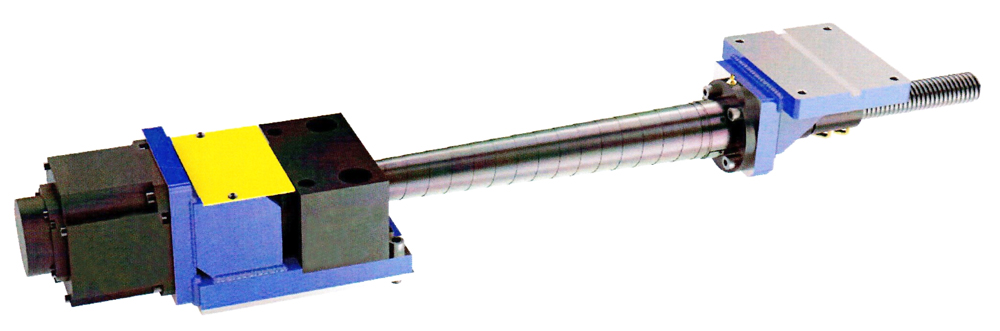

Mechanical aggression is one of the main threats to industrial machinery, especially in environments where exposure to aggressive agents is constant. To ensure that the equipment operates optimally for as long as possible, it is necessary to implement specific solutions that provide effective protection against aggression. An innovative and highly effective method for this purpose is the use of metal spirals.

Designed to protect key components such as spindles, guide columns and threads of machinery, metal spirals offer exceptional defense against dirt, chips and other mechanical aggression. In addition, their robust structure makes them an excellent choice for oily industrial environments, where protection against dust and other contaminants is essential for the proper functioning of the equipment.

Benefits of metal spirals for protection against mechanical aggression

Metal spirals offer high-quality mechanical protection, in difficult industrial conditions. Below are some of the main benefits of using metal spirals in machinery exposed to difficult environments:

Resistance in oily environments

Unlike other protection methods, metal spirals are ideal for environments where oil is a common component. The metal structure is not degraded or affected by the presence of industrial oils, making them an excellent solution for protecting screws and guide columns.

Protection against mechanical aggression and dirt

In industries where machinery is exposed to dirt particles or metal shavings, metal spirals act as a physical barrier that prevents these particles from coming into contact with sensitive parts of the machine. This not only reduces the risk of corrosion, but also minimises premature wear caused by external agents.

Easy installation and maintenance

Thanks to a packaging system designed to facilitate assembly, metal spirals are easy to install. In addition, its special design allows for effortless compression and extension, making it easy to access for maintenance when necessary.

Features of metal spirals

Metal spirals are manufactured using a special method that ensures optimum strength in both horizontal and vertical working conditions. Below are some of their key features:

Easy compression and extension

One of the advantages of these spirals is that their design allows them to be compressed and extended quickly and without generating excessive stress on the machinery. This is particularly useful in applications where components are constantly moving, as they do not affect the performance of the equipment.

Minimal unevenness in horizontal work

When metal spirals are installed on machines that operate in a horizontal position, the unevenness they present is minimal. This ensures that the machinery operates with greater stability, reducing the risk of misalignment or uneven wear on its parts.

Slight lateral deviation in vertical work

For machines that operate in a vertical position, metal spirals only present a slight lateral deviation. This detail is important to ensure that the protection does not interfere with the precision of the movements of the spindles or guide columns, something fundamental in high-precision industrial operations.

Why metal spirals are the best choice for protection against mechanical aggression

When selecting a protection method against mechanical aggression for industrial machinery, it is crucial to consider not only the solution’s effectiveness in prevention, but also its impact on equipment performance and maintenance. Metal spirals stand out for their ability to meet these requirements and offer additional benefits.

Adaptability to different industrial environments

Whether your machinery is located in an environment with high concentrations of dust or in an oily environment, metal spirals provide the necessary protection. They are not easily recharged with dust or fine swarf, making them an ideal choice even in aggressive industrial environments.

Long-term durability

The metal from which the spirals are made is designed to withstand adverse conditions for long periods. This reduces the need to replace guards frequently, which in turn reduces the costs associated with machinery maintenance and repair.

Conclusion: Protect your investment with metal spirals

Using metal spirals to protect industrial machinery against mechanical aggression is not only an effective solution, but is also cost-effective in the long term. By extending the life of critical components such as spindles and guide columns, these guards help keep machinery running at its best and reduce downtime due to failure or repair.