Introduction

At the heart of any modern industrial plant, machine guarding plays a critical role. Especially in the case of large-format machinery, where the dimensions, forces involved, and operational risks are greater, customizing guards is not optional: it’s essential.

Industrial bellows, telescopic covers, fixed barriers, and specific dynamic solutions are essential to maintaining safety, optimizing operations, and ensuring machine durability.

Below, we explain how to customize guards for large-format machines, which materials are ideal, and what mistakes you should avoid if you want to maximize your investment in industrial safety.

Why customize industrial machinery guards?

Large machinery requires machine guards tailored to its specific use and environment. Not all risks are the same, nor do all machines operate under the same conditions.

Customization means:

● Ensuring maximum safety for operators and the plant.

● Optimizing maintenance, facilitating access without cumbersome disassembly.

● Complying with international safety regulations such as ISO 13849 and ISO 14120.

● Increasing the lifespan of the machine and its sensitive components.

Furthermore, custom-fitting guards such as reinforced bellows or industrial curtains allows moving parts to be protected without hindering productivity.

Main challenges in protecting large-format machinery

Protecting large-format machinery involves overcoming challenges such as:

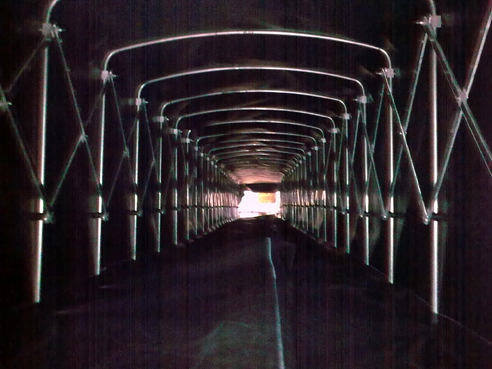

● Large travel distances for axes and carriages.

● High travel speeds.

● Areas that are difficult to access for maintenance.

● A variety of operations: cutting, machining, printing, handling of large parts.

In this case, machine protection bellows are key to protecting guides, spindles, and transmission systems from external agents such as dust, chips, or liquids.

Key factors for designing custom guards

-

Effective machine guard design requires consideration of:

● Operation-specific risk analysis.● Functional compatibility: The guard should not interfere with machine operation.

● Correct selection of materials: thermal, chemical, and mechanical resistance.

● Ease of installation and maintenance: Bellows should be accessible and replaceable.

The design should be robust yet flexible, protecting without restricting the machine.

Types of guards for large machinery

There are multiple solutions that, when combined, offer complete protection:

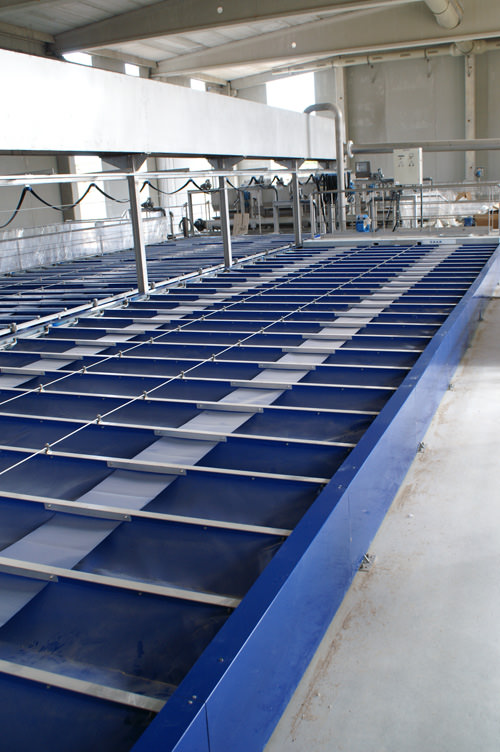

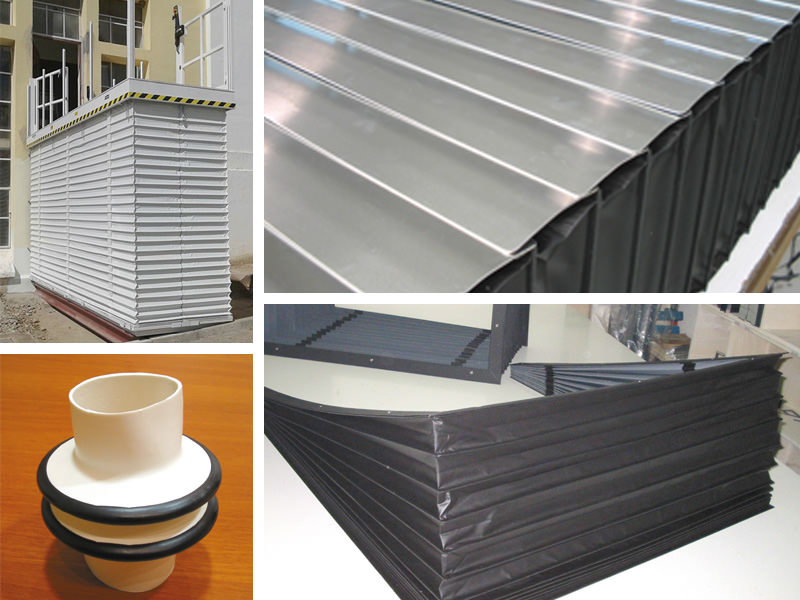

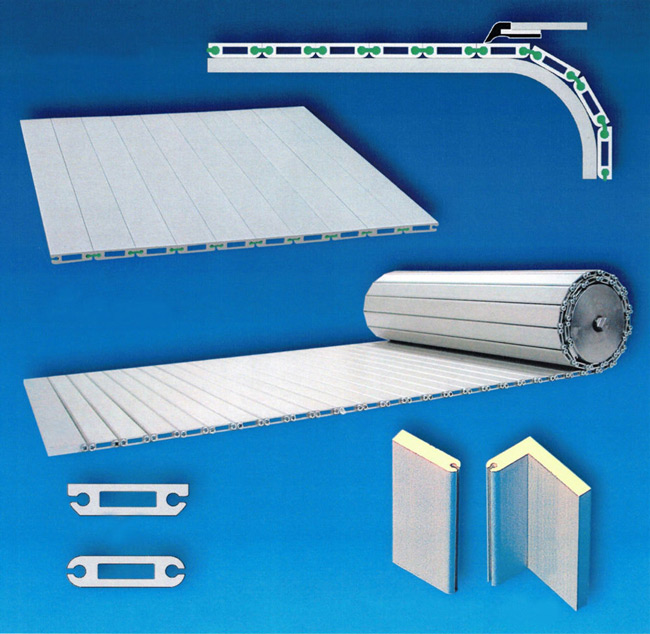

● Telescopic covers: protect vertical and horizontal moving areas.

● Industrial bellows: flexible, durable, and adaptable to linear paths and joints.

● Roller shutters: for quick closure of work areas.

On large-format machinery, bellows are essential for covering dynamic movements where rigid covers would be unfeasible.

How to conduct an effective risk analysis before designing guards

Before manufacturing any machine guard, it is essential to conduct a thorough analysis that includes:

● Identification of risk zones: entrapment areas, hot zones, moving parts.

● Frequency and impact assessment: how many times an operator is exposed to the risk and the severity of a potential incident.

● Determination of protective measures: physical (barriers, bellows), electronic (sensors, emergency stops), or operating procedures.

An accurate analysis prevents unnecessary overprotection or, worse still, underestimation of critical risks.

Ideal materials for large-screen protection

Choosing the right material is just as important as designing the protection well:

| Material | Applications |

| Stainless steel | Areas of high chemical or moisture exposure. |

| Anodized aluminum | Lightweight, high-strength enclosures. |

| Transparent polycarbonate | Visibility and impact resistance. |

| Technical textiles (Kevlar, reinforced PVC) | Bellows resistant to extreme temperatures or abrasion. |

For industrial bellows, materials such as reinforced PVC or special technical fabrics offer an excellent combination of strength, flexibility, and durability.

Common mistakes when customizing machine guards

Avoid these critical failures:

● Generalizing solutions: Each machine has its own unique features.

● Forgetting ease of maintenance: Fixed guards complicate overhauls.

● Underestimating dynamic loads: Guards fail under vibrations or impacts.

A small mistake can multiply costs and increase unnecessary risks.

How to choose the ideal supplier for custom guards?

Before deciding, make sure your supplier:

● Offers demonstrable experience in large formats.

● Works with certified materials.

● Designs guards tailored to each machine and use.

● Provides after-sales technical support.

Choosing the wrong one can lead to costly rework or, worse, legal risks.

Maintaining guards on large-scale machinery

A well-maintained guard system:

● Extends its useful life.

● Maintains operational efficiency.

● Prevents unexpected failures.

In particular, the bellows should be inspected periodically for cuts, tears, or debris buildup.

Custom-made protections, a strategic factor in Industry 4.0

Properly protecting your large-format machinery is not just an act of responsibility: it’s a direct investment in competitiveness, durability, and operational success.

If you’re looking for customized solutions in machine protection, industrial bellows, and advanced safety systems, contact us today. Our expert team will help you design protections that not only comply with regulations but also boost your productivity.