Poor guarding design not only puts the machine at risk, it puts people at risk.

When a machine fails due to a lack of guarding, the cost goes beyond replacement costs. Production is lost, the operator is exposed, and the safety of the entire plant is compromised. What’s most worrying is that, in most cases, this situation was avoidable from the start.

In this article, we analyze the most common mistakes when selecting machine guarding elements and how to avoid them with a strategy based on real technical solutions, not improvisation.

Mistake 1: Selecting Bellows by Dimensions Only

The production of bellows and machine guards requires much more than measuring length, width, and height. A bellows can have the correct dimensions and still fail within weeks if it’s not adapted to the environment:

- High temperature or exposure to steam.

- Abrasive particles in suspension.

- Contact with oils, coolants, or chemicals.

- Continuous work rate, without thermal breaks.

How to avoid it: Choose suppliers who study the operating environment. At Lluis Creus, materials are selected based on actual use, not available stock.

Mistake 2: Installing guards that interfere with sensors or access points

A common mistake in automated environments is installing covers, curtains, or bellows that interfere with:

- Optical or inductive readers.

- Cameras or limit switches.

- Inspection or maintenance areas.

This causes reading errors, blockages, and the need for constant disassembly, ultimately affecting productivity and safety.

How to avoid it: Design your guards with the entire system in mind. A smart solution not only protects, but also respects the functionality of the equipment.

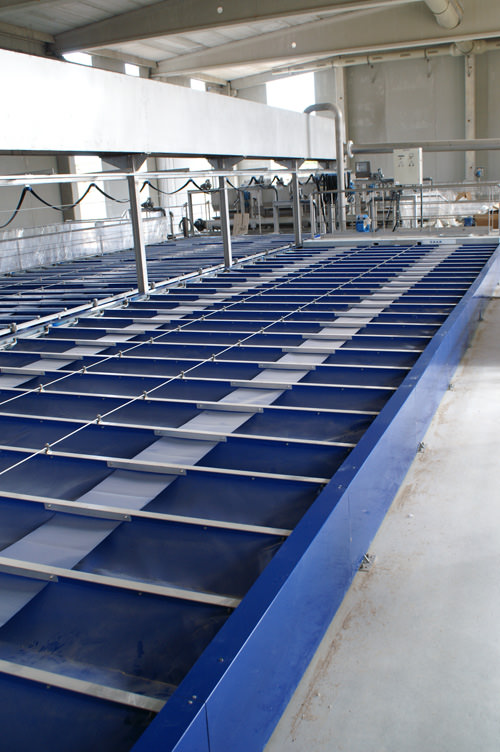

Mistake 3: Using inappropriate materials for aggressive environments

In plants such as wastewater treatment plants, chemical industries, or metallurgical plants, conventional materials are not resistant. It is common to see cracked casings or deformed bellows due to:

- Continuous exposure to moisture or splashes.

- Extreme thermal cycles.

- Corrosion caused by acids or bases.

How to avoid it: Consider solutions such as reinforced polyurethane, technical silicone, or fabrics with specific coatings. Each environment requires its own response.

Mistake 4: Relying on universal catalogs or marketplaces

In many companies, the first impulse is to search for a “compatible” bellows on industrial marketplaces. Although quick and cost-effective in the short term, this decision often leads to:

- Forced assembly or unstable adaptations.

- Premature failures due to material incompatibility.

- Constant replacements and accumulation of useless stock.

How to avoid it: Prioritize the production of custom bellows and machine protection elements, with suppliers who understand your real working conditions.

Mistake 5: Not involving the maintenance team in the decision

Often, the selection process is delegated to purchasing without considering the practical implications. This results in solutions that:

- Difficult access for lubrication or cleaning.

- Break during disassembly.

- Require unnecessary additional tools or steps.

How to avoid it: Involve maintenance managers and operators from the beginning. They are the ones who best understand the weak points and day-to-day needs.

Bonus: Not auditing existing protections

Many companies only act after a breakdown. But waiting for a failure to review the protection is a mistake. The lack of a preventive review can lead to occupational hazards and avoidable losses.

How to avoid it: Schedule an annual technical audit of all protections. Lluis Creus offers this service, which includes a materials review, design adjustments, and improvement proposals.

Conclusion

Machine protection is not an add-on. It is an integral part of the production system. And failure to design or select it directly impacts efficiency, safety, and operating costs.

At Lluis Creus, we work with a technical and industrial approach, adapting each bellows, cover, or protection system to each client’s actual environment. Because the best protection is the one that never interferes… and never fails.