When is it advisable to incorporate a fire-retardant treatment into bellows?

In industrial machinery protection, fire-retardant treatment is often incorporated late, poorly, or due to external requirements. In many projects, it appears as an added requirement at the end of the process, when in reality it should be part of the initial risk...

What type of bellows best withstands the constant humidity of a wastewater treatment plant?

Wastewater treatment plants (WWTPs) represent one of the most demanding environments for any mechanical protection element. The combination of constant humidity, the presence of chemicals, corrosive atmospheres, and continuous operation makes bellows a critical...

Your machine isn’t failing because it’s old. It’s failing because it’s lost its protection.

In many industrial plants, the problem isn’t that the machine is old. The problem is that the protective bellows are broken, degraded, or original replacement parts are simply no longer available. When the manufacturer stops supplying spare parts, the...

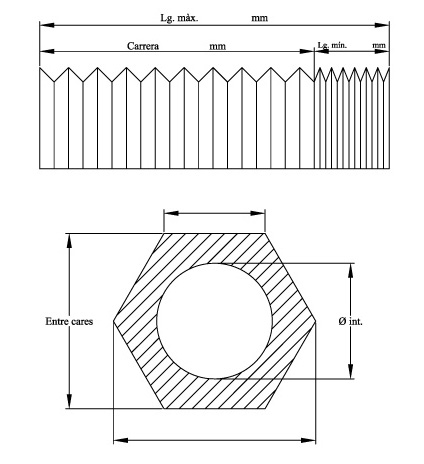

Practical guide: how to measure correctly to order a new bellows

One of the most common mistakes when replacing a bellows isn’t in the material or the design, but in the measurement. An incorrectly measured bellows creates stress, deforms, interferes with machine movement, or fails prematurely. And when that happens, the...