For any type of manufacturing to be at its best and of the highest possible quality, good machinery is necessary. To achieve this, it is not only necessary to have high-quality machines, but also to know how to maintain and protect them so that they do not break down and can continue to work properly. In this article, we will focus on an essential component: protection bellows for linear guides.

What are bellows for linear guides?

Linear guides are the component responsible for producing the interaction between the mobile and static parts of the machine.

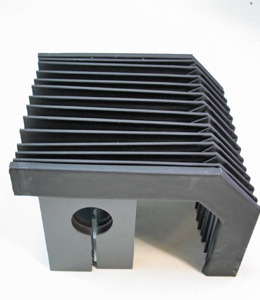

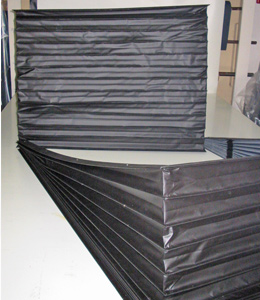

Bellows for guides are a mechanism to protect this type of component, which means that the machine is protected from external forces and does not wear out with time and use.

Why should you use bellows for guides?

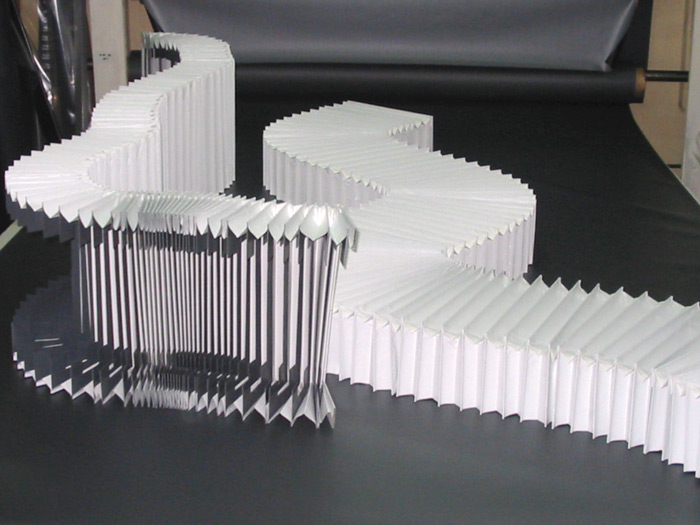

The bellows manufactured for the guides of the machines have different shapes which adapt perfectly to any design and configuration: single-guideway, multi-guideway, complex, etc. Bellows are also available in different types of materials.

In general, as mentioned above, bellows extend the working life of all machines, as they prevent certain failures or breakdowns from occurring that could impair a machine’s overall performance.

On the other hand, protecting the machine allows for a longer service life and therefore saves costs and optimises resources. By using bellows, the company is therefore indirectly investing in greater efficiency.

In addition, bellows can be adapted to almost any product and machine model, allowing a great deal of flexibility when choosing these materials to protect machines.

To summarise, the use of bellows optimises performance from all points of view. If you would like more information about how bellows are used, please contact us and we will explain all the options in detail.