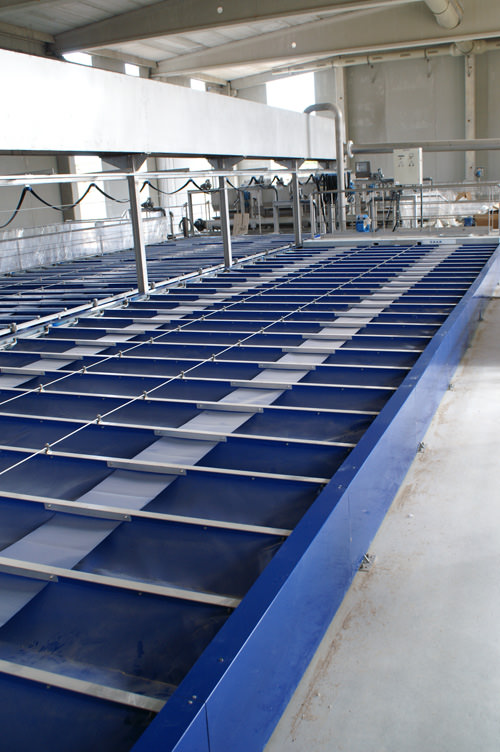

Wastewater treatment plants (WWTPs) represent one of the most demanding environments for any mechanical protection element. The combination of constant humidity, the presence of chemicals, corrosive atmospheres, and continuous operation makes bellows a critical component. An error in material selection or design is not usually immediately apparent, but it eventually leads to premature failures, mechanical blockages, and unplanned shutdowns.

Humidity is not just water

One of the most common mistakes is treating humidity as an isolated factor. In a wastewater treatment plant, humidity is usually accompanied by:

- Chemical vapors

- Constant condensation

- Continuous splashing

- Sludge and suspended particles

This means that the bellows must not only be watertight, but also resistant to long-term chemical and mechanical degradation.

Key technical requirements

To withstand constant humidity, a bellows must meet four basic requirements:

- Not absorb water: absorption leads to a loss of mechanical properties.

- Maintain elasticity in saturated environments.

- Resist chemical attacks common in purification processes.

- Prevent internal accumulation of liquid or residue.

Most suitable materials

Coated technical fabrics (PVC, polyurethane, or special elastomers) are, in most cases, the most balanced solution. They allow for:

- Watertight welds

- Smooth, easy-to-clean surfaces

- Low moisture absorption

Specific technical rubbers can work well in low-traffic areas, provided they are formulated for immersion or saturated environments. Not all rubbers are suitable for this application.

Leather, although very mechanically resistant, is only recommended in wastewater treatment plants when applied with specific water-repellent treatments and in areas where abrasion is the dominant factor.

Importance of design

Design is just as important as the material:

- Slopes that facilitate drainage

- Avoid tight folds where moisture can accumulate

- Watertight fastening systems

Conclusion

In wastewater treatment plant environments, there is no universal bellows solution. Durability depends on the correct combination of material, design, and actual operating conditions. A prior technical analysis drastically reduces breakdowns and maintenance costs.