Manufacturing a custom industrial bellows is not a simple process of copying or selecting a standard design. It requires a comprehensive and meticulous design that considers everything from the operating environment to the specific movements of the machinery it will protect. This technical and collaborative approach is key to obtaining industrial protective bellows that meet the strength, durability, and safety requirements of the most demanding industrial environments.

Analysis and study of the installation environment

The first fundamental step is to gather detailed data about the environment where the bellows will be installed. This involves analyzing the thermal, chemical, and mechanical conditions, including:

- Ambient temperatures and temperatures generated during the process.

- Presence of abrasive agents, dust, oils, or chemicals.

- Types of movements to be protected: linear, telescopic, or rotary.

- Duty cycles, speeds, and critical bending angles.

This technical knowledge prevents premature failures and allows for the selection of appropriate resistant materials for the bellows, guaranteeing its performance under real and extreme conditions.

Custom bellows selection and design

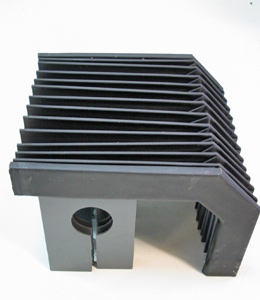

Based on the previous analysis, the next phase is selecting the bellows type and its technical design. The most common types include:

- Cylindrical and conical bellows for protecting hydraulic and pneumatic rods.

- Bellows for linear guides, which are usually rectangular or have a variable cross-section depending on the protected component.

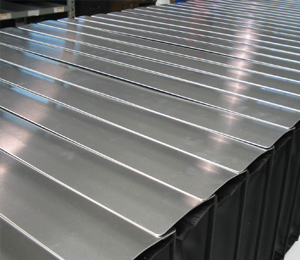

- Metal bellows for applications with high thermal or pressure requirements.

The design is created using CAD software, where dimensions, folds, waves, and fastening systems such as flanges, Velcro, or racks are modeled, adjusting each aspect to ensure compatibility with the machinery and facilitate preventive industrial maintenance.

Industrial manufacturing process

The manufacturing of bellows varies depending on the material and design chosen, but typically includes the following technical processes:

- Cutting and shaping of technical materials such as PVC, polyurethane, silicone, or specialized fabrics, each selected for its chemical and thermal resistance.

- Specialized stitching and heat sealing to ensure watertightness and durability against contaminants.

- Formation of waves or folds, which in metal bellows is done using hydraulic presses and forming dies, guaranteeing flexibility and pressure resistance.

- Application of additional treatments, such as anti-wear coatings or external reinforcements, to extend the component’s lifespan.

This process guarantees a dimensionally accurate component with technical properties tailored to the specific function of physical protection, preventing failures that could cause unexpected downtime.

Quality control and testing

Before shipment to the plant, each bellows undergoes rigorous quality control, where the following are evaluated:

- Resistance to abrasion, fatigue, and chemical agents.

- Recovery capacity after compression and extension cycles.

- Dimensional fit and compatibility with the intended mechanical environment.

This control ensures that the product meets the required industry standards and withstands the intended environment for its use, contributing to industrial safety and reduced operating costs.

Installation and planned maintenance

Finally, the industrial bellows is installed according to technical specifications to maximize its performance and facilitate future inspections. Proper installation and a tailored preventive maintenance protocol optimize durability and reduce downtime related to protective failures.

This detailed process of designing and manufacturing a custom industrial bellows, based on rigorous technical analysis and manufacturing under industry standards, stands out as a fundamental pillar in the protection of critical machinery. Lluis Creus, with its century-long experience, develops these processes to provide effective physical protection elements that guarantee productive continuity and safety in demanding environments.