In the industrial protection sector, reducing machine downtime is a strategic priority for preventive maintenance managers and plant managers. The key lies in the use of industrial bellows, industrial covers, and custom protection solutions that meet the specific requirements of each environment and operation.

The value of physical protection in industrial safety

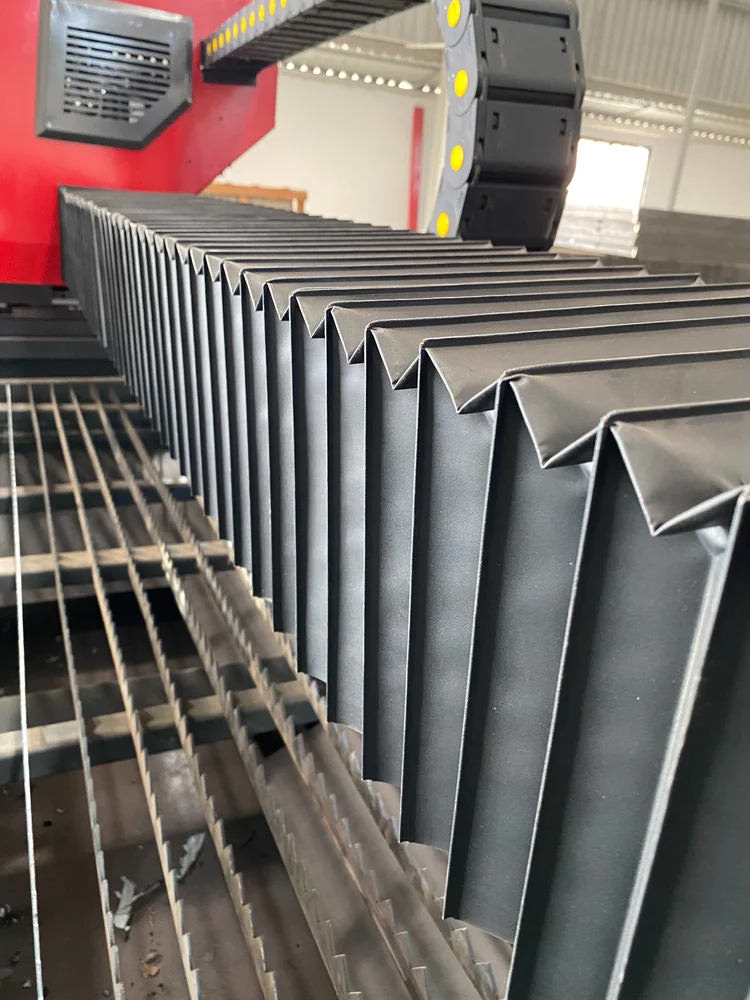

Resistant materials are essential for protecting machinery from external agents, dust, debris, and high-friction conditions. Degradation of physical protection leads to failures and unplanned downtime; therefore, the correct selection and design of industrial covers and bellows directly impacts equipment longevity, industrial safety, and operating costs.

- Industrial consulting helps optimize material selection and industrial design for each application, adapting protection to the actual needs of the process.

- A systematic industrial equipment inspection and corrective maintenance plan allows for anticipating component replacements before they impact production.

Traditional strategies for reducing maintenance downtime

The correct implementation of preventive maintenance, supported by robust, custom-made industrial protection, can achieve downtime reductions of up to 30%, according to the experience of leading manufacturers and industry studies.

- Technical personnel should schedule periodic inspections of bellows, covers, and other industrial protection elements, document their wear, and adapt the replacement cycle accordingly.

- Custom manufacturing and the use of certified materials guarantee higher performance, lower emergency expenses, and improved operational optimization.

Cost reduction and production continuity

The use of custom-made industrial protection, with proper guidance and planned maintenance, not only protects equipment but also increases machinery durability and operational safety. Companies like Lluis Creus excel at providing robust industrial covers and bellows built according to longevity and reliability criteria, supporting industry in its pursuit of efficiency and reduced critical downtime.