In modern industry, the proper functioning of machinery is essential for productivity and operational efficiency. However, factors such as the accumulation of waste, mechanical wear and exposure to external agents can affect the performance of equipment and generate high maintenance costs.

Industrial bellows play a key role in protecting moving components, preventing the entry of contaminants and reducing the impact of friction and repetitive motion. Although they often go unnoticed, these elements extend the life of machinery, reduce downtime and optimize safety in the work environment.

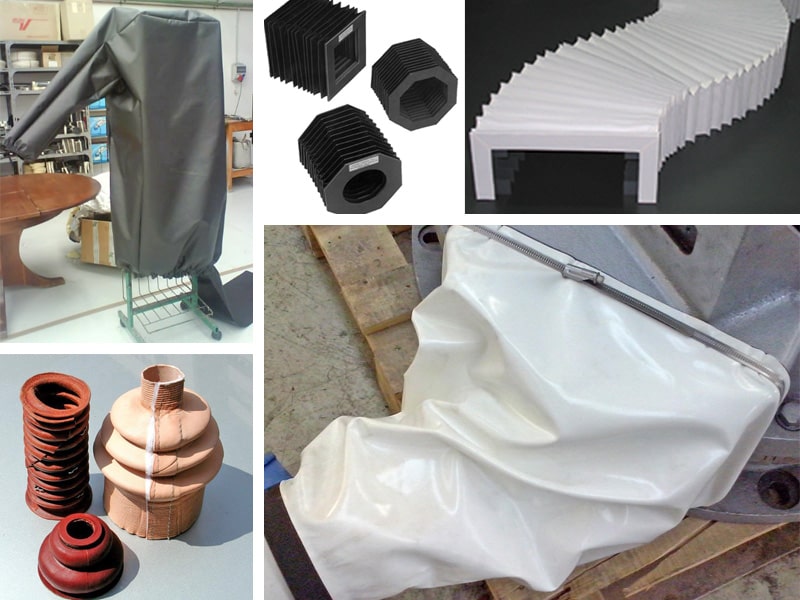

At Lluis Creus, we offer customized solutions in industrial bellows, guaranteeing the best protection for each type of equipment.

What are industrial bellows and what are they used for?

Industrial bellows are flexible protection elements that are installed on equipment with moving parts to prevent the accumulation of waste and avoid mechanical damage. Their design allows them to adapt to different types of movements, ensuring total protection without interfering with the operation of the machinery.

They are mainly used to:

● Cover spindles and linear guides in CNC machines and machining centers.

● Protect hydraulic cylinders from dirt, oils and abrasive particles.

● Prevent contact with external agents in demanding industrial environments.

● Reduce premature wear caused by friction and repetitive movements.

Industrial bellows can be made from various materials depending on the application environment, such as technical fabrics, polyurethane, silicone or fiber-reinforced materials.

Benefits of industrial bellows in machinery protection

1. Prevention of damage and premature wear

Industrial machines work in demanding conditions where dust, chips and industrial liquids can affect their internal components. Industrial bellows prevent these elements from coming into contact with spindles, guides and cylinders, minimizing wear and the need for costly repairs.

2. Reduced maintenance costs

Equipment maintenance represents an important part of any company’s operating budget. By installing industrial bellows, the frequency of corrective maintenance is reduced and premature mechanical failures are avoided, allowing for lower spare parts and repair costs.

3. Increased safety in the work environment

Equipment with exposed moving parts can pose a risk to operators. Industrial bellows provide a safety barrier that prevents access to moving components, preventing entrapment and accidents.

4. Protection against external agents in aggressive environments

Industries operating in environments with high temperatures, humidity or exposure to chemicals require protection solutions adapted to these conditions. Industrial bellows made of heat, corrosion and abrasion resistant materials guarantee optimal performance even in extreme conditions.

5. Prolongation of the useful life of machinery

The use of suitable industrial bellows helps to keep moving parts in optimal condition for longer, avoiding premature wear and allowing equipment to operate efficiently for more years.

Types of industrial bellows and their applications

There are different types of industrial bellows, each designed for specific applications within the industry.

1. Square or telescopic bellows

● Used in CNC machines, milling machines and machining centers.

● They protect spindles and linear guides from the accumulation of chips and debris.

● Available in materials resistant to oils and coolants.

2. Bellows for hydraulic cylinders

● Designed to protect cylinders from contamination and abrasive agents.

● Made of flexible materials resistant to hydraulic fluids.

● They adapt to linear movements without compromising the performance of the cylinder.

3. High-tightness bellows

● Specially designed for environments with fine dust and suspended particles.

● Made of technical fabrics with special coatings.

● They are used in automated production lines and pharmaceutical or food environments.

4. High temperature resistant bellows

● Made of silicone or fiberglass materials to resist heat.

● Applied in industrial ovens and machinery exposed to high temperatures.

● Prevents component degradation in extreme environments.

Considerations for selecting an industrial bellows

To ensure maximum protection and efficiency, it is important to choose the right bellows according to the working conditions and type of machinery.

Key factors to consider:

● Type of movement: linear, telescopic, articulated or multidirectional.

● Exposure to contaminants: chips, dust, oils or coolants.

● Environmental conditions: humidity, temperature, chemicals.

● Bellows material: polyurethane, silicone, technical fabric or reinforced material.

● Safety requirements and applicable regulations.

At Lluis Creus, we offer personalized advice for the selection of industrial bellows adapted to each specific need.

Conclusion

Industrial bellows are essential elements in the protection of machinery and the reduction of operating costs. Their installation prevents premature failures, reduces downtime and guarantees safety in the industrial environment.

At Lluis Creus, we provide tailor-made solutions in industrial bellows, adapted to different sectors and production environments. We have a wide range of materials and configurations to guarantee maximum protection and durability.

If you are looking to optimize the performance of your machinery and reduce maintenance costs, contact us for technical advice and to learn about our customized solutions.