In industrial environments with limited space, ensuring safety without compromising the operability of machinery is a challenge. Small areas can increase the risk of collisions, debris build-up and mechanical failures if the appropriate protection systems are not in place.

Lluis Creus S.L. offers specialized solutions for the protection of machinery and people, with products designed to optimize the use of space without affecting functionality. Square bellows, metal spirals, aluminum shutters and protective covers are key elements to maintain safety in compact environments.

Below, we explore the main challenges and solutions to optimize safety in small spaces.

Safety challenges in small spaces

When space is limited, risks increase due to several factors:

● Increased risk of entrapment and collisions: The proximity between operators and machinery increases the possibility of accidents.

● Accumulation of dirt and debris: Chips, dust and liquids can affect the operation of machines.

● Difficulty installing bulky protection systems: Compact and efficient solutions are required.

● Limited access for maintenance and repairs: Equipment must have protections that facilitate its storage without taking up too much space.

To minimize these risks, it is key to choose security solutions specifically designed for small areas.

Protection solutions for machinery and people in small areas

Below, we analyze the most effective solutions from Lluis Creus S.L. to optimize safety in compact environments.

1. Square bellows for protection in tight spaces

The square bellows from Lluis Creus S.L. are a compact and effective solution to protect mechanical components without interfering with operation.

● They protect guides and spindles from dust and debris without taking up unnecessary space.

● They allow controlled folding, adapting to small areas.

● They extend the useful life of the equipment by reducing wear.

Their modular design makes them an ideal option for industries with space limitations.

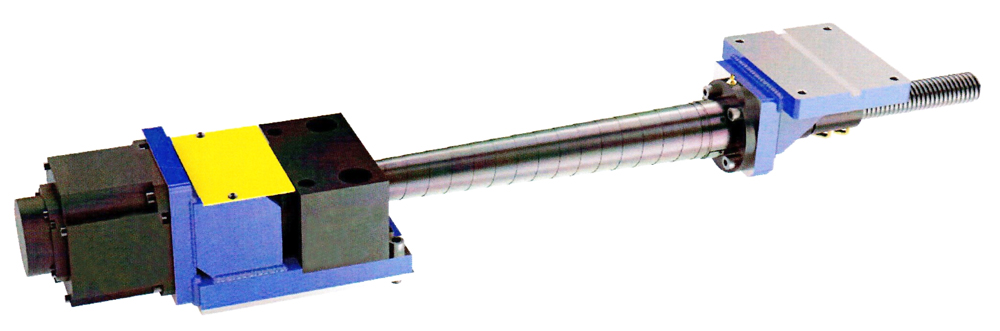

2. Metal spirals to protect spindles and guide columns

Metal spirals are an excellent alternative for protection in compact environments, since they do not require bulky structures.

● They cover spindles, guide columns and wires against dirt, chips and mechanical aggression.

● They are flexible and adapt to maximum openings without compromising the operation of the machine.

● Their metal structure guarantees durability and resistance in demanding conditions.

These spirals offer effective protection without compromising the mobility of the equipment.

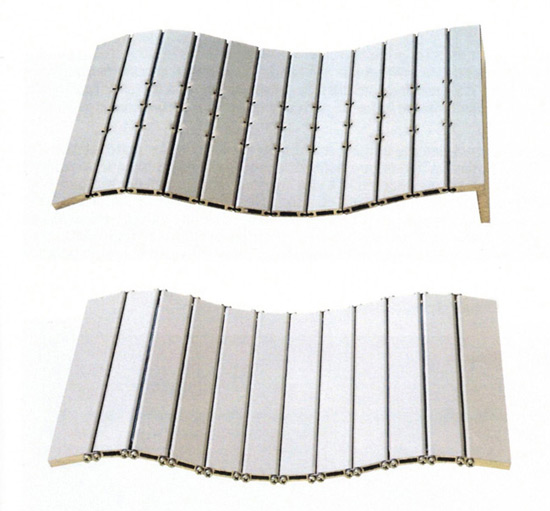

3. Aluminum shutters for safety in small spaces

The aluminum shutters from Lluis Creus S.L. provide a physical and mechanical barrier in compact industrial machines.

● They protect against intense aggression without taking up additional space.

● Resistant to liquids and other external agents.

● Widely used in machine tools and production systems with small areas.

Their retractable design allows efficient integration in environments where every centimeter counts.

4. Protective covers for moving components

In machinery with non-linear movements, covers, compensators and sleeves provide adaptable protection without requiring rigid structures.

● Designed to cover moving parts without controlled folding.

● Total protection against dust, liquids and other external agents.

● They adjust to different configurations without interfering with the performance of the equipment.

Their flexibility makes them an ideal option for environments with space restrictions.

5. Adaptation of machinery to optimize safety

In cases where existing machinery does not comply with safety regulations, Lluis Creus S.L. offers solutions for adaptation and adaptation of equipment.

● Study and execution of projects to improve safety in compact industrial environments.

● Adaptation of old machines without CE marking to comply with current regulations.

● Implementation of customized protections according to the client’s needs.

These solutions allow improving safety without having to completely change the machinery.

How to choose the best protection solution in confined spaces

To select the best safety strategy in compact areas, the following aspects must be considered:

1. Identify critical risk points: Evaluate which areas are most prone to accidents or accumulation of waste.

2. Opt for compact and modular solutions: Choose protections that adapt to confined spaces without affecting operation.

3. Comply with safety regulations: Ensure that the selected products comply with standards such as ISO 13849, ANSI B11 or the EU Machinery Directive.

4. Facilitate maintenance and accessibility: Implement protections that allow easy access for checks and repairs.

Conclusion

Protecting machinery and people in confined areas requires innovative solutions that maximize safety without compromising operational efficiency.

Lluis Creus S.L. solutions, such as square bellows, metal spirals, aluminium shutters and protective covers, are designed to offer effective protection in compact spaces. Implementing them allows reducing the risk of accidents, minimising wear and tear on machinery and optimising the use of available space.