In industry, operating speed is key to productivity, but it also represents a significant risk to safety. Without adequate protection, rapid movements can lead to workplace accidents and damage to machinery, impacting efficiency and maintenance costs. Lluis Creus S.L. offers machinery and people protection solutions designed to mitigate these risks without compromising operability.

Square bellows, metal spirals, aluminum shutters and protective covers are some of the systems that help maintain safety in high-speed environments. In this article, we analyze the main challenges and the most effective solutions for protection in these conditions.

Challenges of speed in industrial safety

The use of high-speed machinery poses several risks:

● Increased risk of collisions: The proximity between operators and moving equipment can cause accidents.

● Accelerated wear: Mechanical components deteriorate rapidly if they are not protected.

● Limited reaction time: At higher speeds, there is less room to correct errors.

● Accumulation of waste and dirt: Elements such as metal shavings can damage spindles and guides if adequate protection is not provided.

The solution to these problems lies in implementing specific protections such as those offered by Lluis Creus S.L., which guarantee safety without affecting operational efficiency.

Protection solutions for high-speed environments

1. Square bellows for controlled movements

Lluis Creus S.L. square bellows are ideal for protecting mechanical components in high-speed machines.

● They protect guides and spindles from dust and debris.

● They reduce wear and extend the life of the equipment.

● They allow controlled bending, adapting to different types of movement.

2. Metal spirals for protection of spindles and columns

Metal spirals are a compact solution to protect key components without interfering with the performance of the machine.

● They cover spindles, guide columns and wires against dirt and chips.

● They resist mechanical aggression even with maximum openings.

● Their metallic design allows high durability and adaptability.

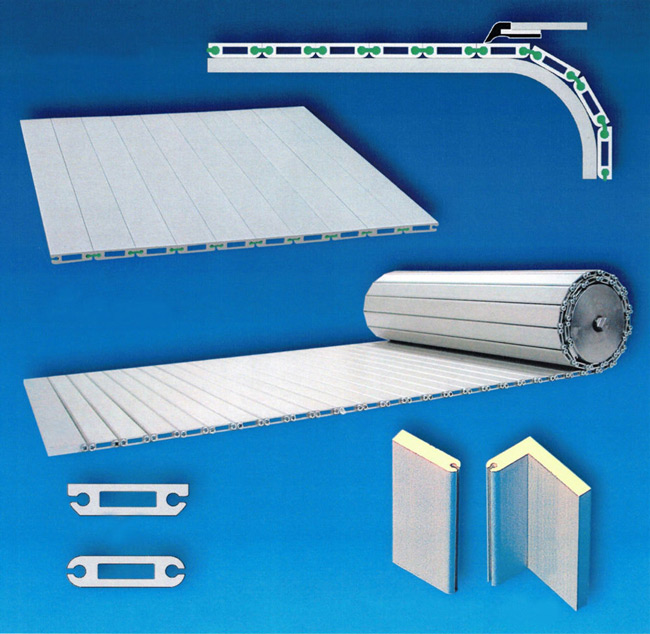

3. Aluminum shutters for mechanical and thermal protection

Lluis Creus S.L. aluminum shutters they offer physical and mechanical protection for high-speed machinery.

● Ideal for environments with intense aggression.

● Resistant to liquids and other elements that may compromise the integrity of the machine.

● Wide application in the machine tool sector.

4. Protective covers for moving parts

Covers, compensators and sleeves are the best solution when the movement is not linear and flexible protection is required.

● Designed to adapt to different machinery configurations.

● They offer total protection without controlled folding.

● Ideal for covering delicate parts or parts in contact with external agents.

5. Adaptation of machinery for greater safety

Lluis Creus S.L. also offers study and execution of projects for adapting machinery to safety regulations.

● Modification of old machines without CE marking.

● Implementation of additional protections to optimize safety in modern industrial environments.

● Customized solutions according to customer requirements.

Conclusion

High speed in industry requires protection systems that ensure both the safety of workers and the performance of machines.

Lluis Creus S.L. solutions, such as square bellows, metal spirals, aluminum shutters and protective covers, are essential to prevent accidents and reduce wear on machinery. Investing in these systems not only improves safety, but also prolongs the useful life of equipment and optimizes productivity.

If you are looking for machinery and people protection solutions adapted to high-speed environments, contact Lluis Creus S.L. to find out the best options for your industry.