Choosing between bellows and covers is crucial to protect industrial machinery from external agents, optimize its performance and prolong its useful life. Both options fulfill specific functions, but their differences in design, materials and applications make one more suitable than the other depending on your needs. In this article, we analyze the advantages and disadvantages of each option, so you can make an informed decision and maximize the efficiency of your operation.

What are bellows and covers?

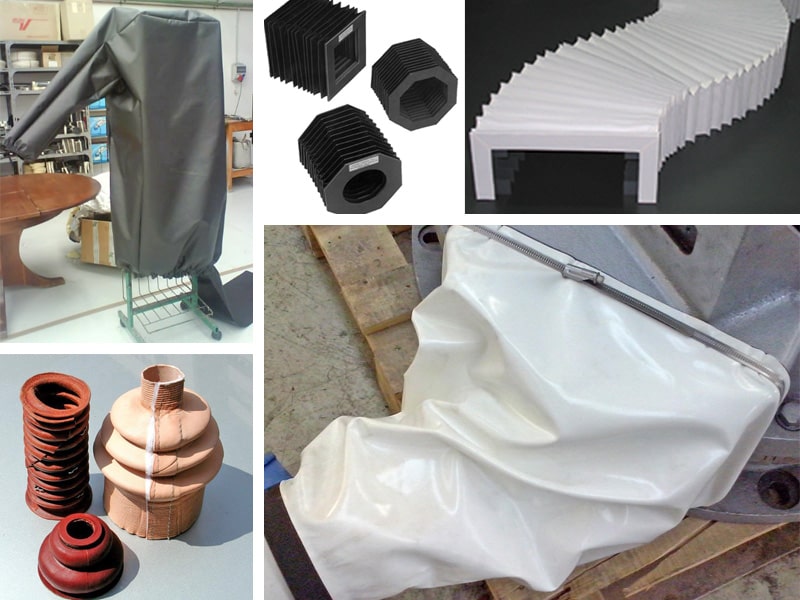

Bellows

Bellows are flexible and resistant structures designed to protect moving components, such as spindles, linear guides or hydraulic cylinders, against dust, humidity, abrasive particles and liquids. Their extensible design allows them to adapt to the continuous movement of the equipment, offering protection without limiting its functionality.

Main characteristics:

● Flexibility and adaptability.

● Wide range of materials (leather, PVC, silicone, among others).

● Ideal for dynamic applications.

Covers

Covers are fixed or removable covers that enclose specific components to protect them from external agents. They are used in applications where movement of parts is limited or non-existent.

Main features:

● Simpler and more static design.

● Made of materials such as plastic, rubber or technical textiles.

● Ideal for stationary components or those with restricted movement.

Bellows vs. covers: key differences

| Appearance | Bellows | Covers |

| Movement | Designed for dynamic movements. | Limited to stationary components. |

| Adaptability | They extend and contract according to the range of action. | They cover fixed or minimally moving parts. |

| Materials | Leather, silicone, PVC, technical textiles. | Plastics, rubber, textile materials. |

| Durability | High, thanks to their reinforced design. | Lower, especially in demanding environments. |

| Applications | Screws, cylinders, linear guides. | Motors, cables, static connections. |

| Cost | Higher due to their complexity. | Generally cheaper. |

When to choose bellows?

1. Applications with constant motion

Bellows are the best option when machinery components are in constant motion. Their extendable design protects without interfering with the functionality of the part.

Examples of use:

● Spindles in CNC machines.

● Linear guides in industrial robots.

● Hydraulic cylinders in presses.

2. Demanding Environments

In environments where machinery is exposed to dust, liquids or high temperatures, bellows offer superior protection thanks to their resistance to external agents.

Ideal materials:

● Leather: For high friction and temperature conditions.

● Silicone: Resistant to chemicals and extreme heat.

When to choose covers?

1. Static or limited movement components

Covering is best suited for machinery parts that do not require continuous movement or have minimal movement.

Examples of use:

● Stationary electric motors.

● Cables or hoses that need additional covering.

● Static connections in hydraulic systems.

2. Low cost applications

If budget is a concern and environmental conditions are not aggressive, covering is an economical solution that meets basic protection requirements.

Advantages and disadvantages of each option

| Advantages | Bellows | Covers |

| Dynamic protection | Maintain their shape and functionality in constant movement. | Economical and easy to install. |

| Resistance | Highly resistant to abrasion, chemicals and humidity. | Sufficient for non-demanding environments. |

| Adaptability | Customizable to cover complex ranges of movement. | Simple, but limited to static applications. |

| Disadvantages | More expensive and complex to install. | Less durable in aggressive conditions. |

How to make the right choice

Key Questions to Define Your Choice

1. Is the component in constant motion or is it static?

○ If it is in motion, choose bellows.

○ If it is static, covers are sufficient.

2. Is the environment aggressive or moderate?

○ For demanding conditions, select bellows with resistant materials.

○ For controlled environments, opt for covers.

3. What is your budget?

○ Bellows are more expensive, but offer greater durability.

○ Covers are economical and suitable for basic applications.

Customized solutions with LLUIS CREUS S.L.

At LLUIS CREUS S.L., we are experts in developing customized solutions for the protection of machinery. With more than 150 years of experience, we manufacture bellows and covers adapted to the specific needs of each client.

Our Advantages:

● High Quality Materials: Leather, silicone, PVC and more.

● Custom Designs: Adapted to the dimensions and requirements of your machinery.

● ISO 9001 Certification: We guarantee quality in all our products.