Heavy machinery is essential to many industries, but it also carries significant risks. To prevent accidents and ensure the safety of workers, companies must comply with strict safety regulations. These regulations are essential to protect both operators and personnel near the machinery. Below, we explore the key regulations that companies must follow to ensure a safe working environment.

Importance of Safety Regulations for Heavy Machinery

Heavy machinery can cause serious accidents if not handled carefully. Safety regulations help mitigate these risks by ensuring that companies take the necessary steps to prevent incidents. Complying with these regulations not only protects employees, but also reduces the possibility of legal penalties, lawsuits, and costly production disruptions.

International Regulations: ILO and OSHA

International regulations established by the International Labour Organization (ILO) and the Occupational Safety and Health Administration (OSHA) are pillars of industrial safety.

● ILO: Focuses on operator training, use of personal protective equipment (PPE), and implementation of risk assessments.

● OSHA: Requires daily inspections of equipment, operator certification, and physical protection measures such as emergency stop systems and safety barriers.

Complying with these regulations ensures that companies implement effective preventative measures to protect workers.

Local and national regulations

In addition to international regulations, each country has specific regulations that companies must comply with. For example:

● European Union: The Machinery Directive requires the CE marking, which certifies that machines comply with EU safety standards.

● Latin America: In countries such as Brazil and Mexico, local regulations govern machinery safety, such as NR-12 and NOM-004-STPS, which establish training, maintenance and physical protection requirements.

Operator Training and Certification

A crucial part of regulations is the training of heavy equipment operators. Companies must ensure that operators receive adequate training and certifications to safely operate equipment. Additionally, ongoing training is essential to keep employees up to date on new technologies and safety protocols.

Protective measures and safety systems

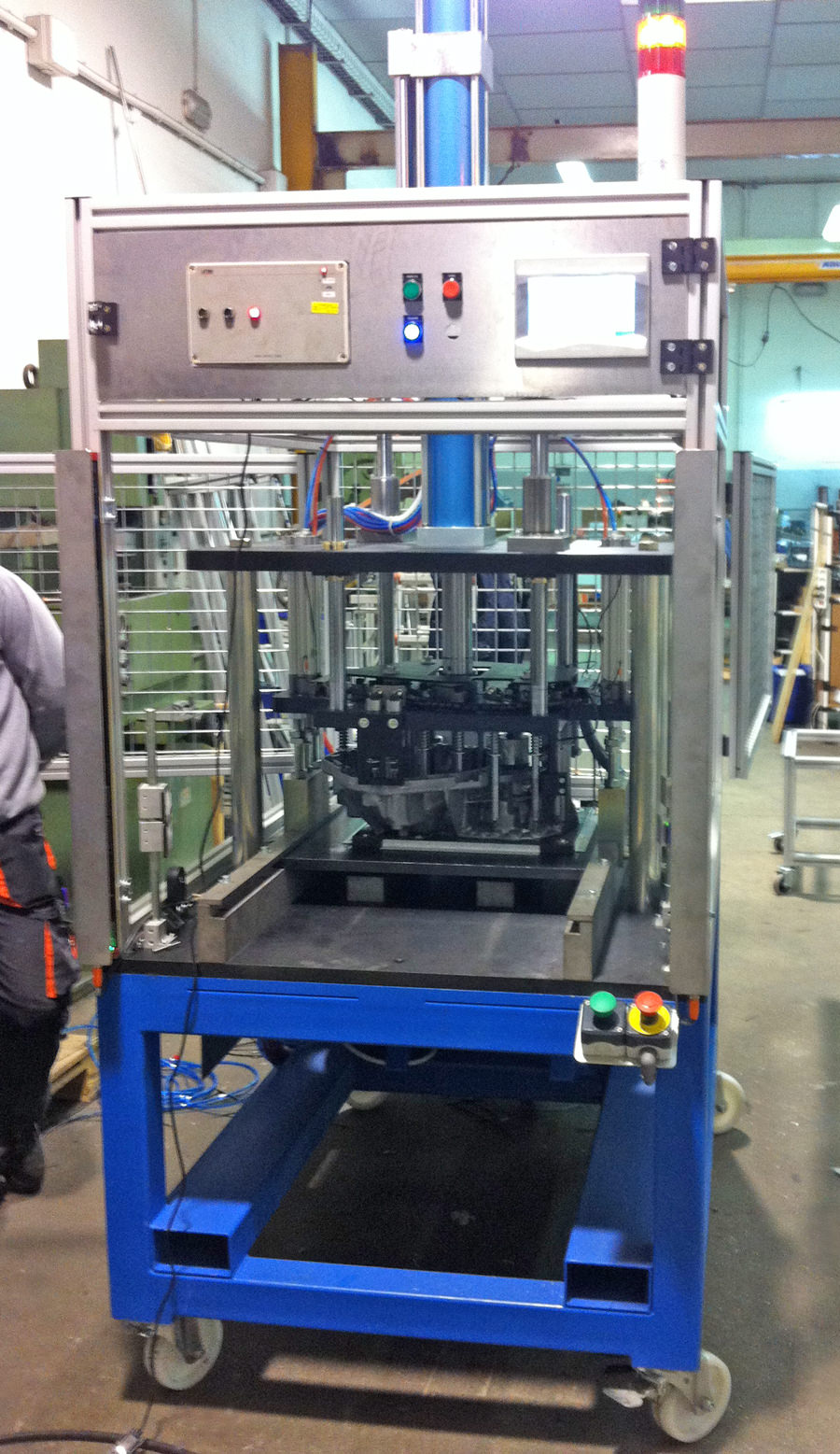

Regulations require the protection of not only operators, but also all nearby workers. Some of the key measures include:

● Demarcated danger zones: Clearly defined areas where only authorized personnel can operate or approach machinery.

● Emergency stop systems: All equipment must have devices to stop operation in the event of imminent risk.

● Physical barriers and signage: To warn workers about dangerous areas and restrict unauthorized access.

Preventive maintenance and records

Regulations also require companies to perform regular maintenance on their equipment to ensure it is working properly. This includes periodic inspections and replacement of worn parts. In addition, companies must keep detailed records of all maintenance activities, repairs and overhauls, which facilitates audits and ensures ongoing safety.